Manufacturing & Services

Electrotherapy Electrode Solutions by Pepin Manufacturing

At Pepin Manufacturing, Inc. (PMI), we specialize in the manufacturing and services required to produce high-quality electrotherapy electrodes for medical and therapeutic applications. With decades of experience in contract manufacturing, we offer scalable, consistent, and cost-effective solutions to support OEMs, private label brands, and healthcare product distributors.

Our approach combines advanced production technologies with precision converting and strict quality assurance, ensuring that every electrode we produce performs reliably and safely in the field. By aligning technical expertise with customer goals, we offer manufacturing solutions that are both innovative and grounded in practicality.

Request A Quote

Home » Electrotherapy » Manufacturing & Services

About Electrotherapy Electrode Manufacturing

For over 30 years, Pepin Manufacturing, Inc. has been a leading manufacturer of electrotherapy electrodes under the Advantrode trademark name.

Our electrodes are best in class thanks to their:

- 100% uniform current dispersion

- Improved reusability

- Ultra-low impedance

Our fully automated processes enable us to continue manufacturing USA-made electrotherapy electrodes at competitive prices, offering a wide variety of TENS units, leadwires and accessories.

End-to-End Manufacturing and Services for Electrotherapy Electrodes

We provide comprehensive manufacturing and services that cover the entire lifecycle of electrotherapy electrode production. From sourcing raw materials to final packaging, Pepin Manufacturing operates as a single-source partner for high-volume, private-label, and specialty electrode products. Our collaborative process includes thorough consultation, design adaptation, and scalable mass production.

Our capabilities include:

- Roll-to-roll electrode fabrication

- Multi-layer lamination

- Precision rotary die cutting

- Custom lead wire attachment

- Hydrogel placement (excluding hydrogel formulation)

- Printing and branding on electrode backings

- Packaging, kitting, and assembly

- In-line inspection and automated defect detection

- Flexible pack-out options for clinical or retail use

Whether you’re seeking full production support or specific contract manufacturing segments, our solutions are tailored to align with your operational needs and product goals. We help companies reduce costs, improve turnaround time, and maintain product integrity from batch to batch.

High-Performance Materials and Layer Integration

Electrotherapy electrodes are only as effective as the materials and processes behind them. That’s why our manufacturing and services place a heavy emphasis on quality material sourcing and integration. We focus on establishing consistency in material properties to ensure electrical efficiency, patient comfort, and longevity.

We work with a variety of electrode component materials, including:

- Conductive films and foils

- Carbon-based substrates

- Medical-grade nonwovens and foams

- PET liners and non-stick release layers

- Adhesive and hydrogel-compatible layers

- Specialized insulation and protective barriers

Using multi-layer lamination, we assemble these components with precise alignment and consistent thickness to meet your specific conductivity and durability requirements. Every product is built for reliable skin contact, even signal transmission, and comfortable use. Our engineers evaluate each configuration to maintain compatibility with device parameters and patient outcomes.

Precision Converting for Electrotherapy Products

Our rotary die cutting and converting operations enable high-speed production of electrodes with tight tolerances. This ensures uniform sizing, pad shape, and adhesive performance across large production runs. As part of our manufacturing and services, we provide customization options for shape, size, lead-out design, and branded labeling to differentiate your product in the market.

Whether you’re producing TENS, EMS, IFC, or other electrotherapy formats, we can scale your product without sacrificing performance or quality. With decades of experience in converting processes, we continually invest in new tooling and automation to optimize yield and reduce waste.

Customization and Private Label Capabilities

Pepin Manufacturing supports OEMs and private-label clients by offering custom branding and packaging services. As part of our manufacturing and services, we can apply client-specific artwork, logos, and product instructions directly onto the electrode backings or packaging. Our design and production teams work closely with clients to create packaging that complies with regulatory guidelines and enhances brand visibility.

Private label capabilities include:

- Custom print layouts

- Branded packaging sleeves or pouches

- Instructional inserts or product guides

- Custom pack-out configurations

- Variable data printing and barcoding

- Clinical kit and retail multipack options

Our goal is to help you launch and distribute electrotherapy electrodes under your brand with minimal lead times and full supply chain confidence. We handle both small-scale test runs and high-volume national rollouts with equal precision.

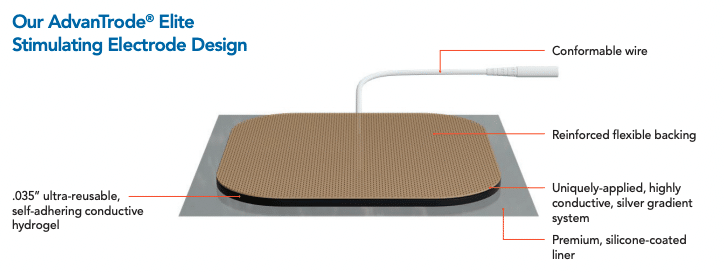

AdvanTrode® Elite

Ultra-high performance electrodes with a uniquely applied conductive pure silver layering system and pure copper lead wires with dispersive lug heads to help achieve best-in-class electrical dispersion and conductivity to maximize patient comfort.

AdvanTrode® Essential

General use electrodes combine quality with value. These cost-effective electrodes provide comfort and maximum reusability without sacrificing quality.

Accessories

Pepin offers electrotherapy accessories and equipment designed for therapeutic uses. Products include lead wires and batteries for TENS units and pain-relieving gel used to equip, maintain and supplement pain-relieving technology.

Quality Assurance and Regulatory Standards

Our manufacturing and services are guided by rigorous quality protocols and compliance with internationally recognized standards. All electrotherapy electrode production is managed with documentation and control systems that support traceability, repeatability, and process validation.

We align with key quality and safety standards, including:

- ANSI and ASTM specifications

- RoHS and CE directives

- CSA and TS requirements

- Cleanroom handling procedures (as required)

- Lot traceability and documented batch records

By maintaining a high standard of quality control at every production stage, we ensure that your product meets both clinical performance demands and market regulations. Our in-house quality team performs routine audits, tests, and process verifications to safeguard every shipment.

Scalable Production for Growing Demand

Our production facility is optimized for high-volume manufacturing, allowing us to support growth without compromising delivery times or product integrity. Clients turn to Pepin Manufacturing when they need a manufacturing and services partner capable of adapting to increased demand, seasonal fluctuations, or new market opportunities.

With multiple converting lines, robust material sourcing partnerships, and flexible production scheduling, we’re built for scalability and dependability. From regional distributors to global healthcare brands, we provide the infrastructure and responsiveness needed for fast-moving markets.

We also offer demand forecasting support, blanket order fulfillment, and just-in-time delivery services to help you manage inventory efficiently and stay responsive to customer needs.

Partner With the Right Electrotherapy Manufacturer

Choosing the right partner for your electrotherapy product line means more than just outsourcing production—it means aligning with a manufacturer who understands your needs and can deliver results. Pepin Manufacturing offers a true partnership through:

- Transparent communication throughout your project

- Full confidentiality and intellectual property protection

- On-time production and delivery

- Technical expertise in electrode application and usability

Our clients value our ability to streamline their manufacturing operations and bring consistent products to market efficiently. We offer both standardized and custom solutions designed to meet diverse business goals.

Industries and Applications We Serve

The electrotherapy electrodes we manufacture are used across a wide range of medical and therapeutic applications, including:

- Pain management (e.g., TENS units)

- Muscle stimulation (e.g., EMS devices)

- Rehabilitation therapy (e.g., NMES systems)

- Athletic training and recovery

- Chiropractic and physical therapy clinics

- Consumer wellness and fitness brands

- Post-operative recovery solutions

With extensive experience across these fields, our manufacturing and services are trusted by leading OEMs, distributors, and private-label brands worldwide. Our flexible capabilities make us an ideal partner for both clinical and consumer-facing applications.

Frequently Asked Questions About Custom Turnkey Manufacturing Solutions

What does “turnkey manufacturing” mean in electrotherapy electrode production?

Turnkey manufacturing means that Pepin Manufacturing manages every step of the electrode production process—from sourcing raw materials and developing product specifications to converting, assembly, packaging, and final quality control. Instead of coordinating with multiple vendors, clients work with a single trusted partner who can handle design, scaling, compliance, and delivery. This reduces complexity, shortens lead times, and ensures product consistency.

How does PMI support product customization for different brands?

Customization is one of our core strengths. We can modify electrode shapes, lead-wire designs, pad sizes, and connector styles to fit your device requirements. Beyond functionality, we also offer custom branding through printing on electrode backings, branded packaging, and tailored pack-out formats. Whether you’re launching a clinical product or a retail line, we can help you differentiate your brand while ensuring regulatory compliance.

What makes Pepin Manufacturing electrodes different from lower-cost overseas options?

Many overseas suppliers focus on price at the expense of consistency, quality, and compliance. At Pepin Manufacturing, all electrodes are made in the U.S.A. under strict quality systems and regulatory frameworks. This means you get electrodes with uniform current dispersion, proven reusability, and low impedance—all backed by documented batch records and traceability. Clients often find that fewer product failures, better patient outcomes, and faster replenishment cycles more than offset the perceived cost savings of offshore options.

Do you provide regulatory support for OEMs and private-label brands?

Yes. We understand that compliance is critical in the medical device industry. While each client maintains responsibility for their device’s regulatory filings, PMI provides documentation, process validations, and quality records that support FDA, CE, RoHS, and other regulatory submissions. We also follow ANSI, ASTM, and CSA standards to ensure that your electrodes meet performance and safety requirements.

Can PMI scale production if my demand grows suddenly?

Absolutely. Our facility is designed to accommodate both steady production and rapid increases in demand. We operate multiple converting lines, maintain long-standing relationships with material suppliers, and use flexible scheduling to respond quickly to client needs. Whether you’re moving from a pilot run to full commercialization or experiencing seasonal spikes, we can adapt without compromising quality or delivery timelines.

What industries benefit most from your custom electrode manufacturing services?

Our electrodes are widely used across healthcare and wellness industries, including pain management, rehabilitation, sports recovery, chiropractic care, and consumer fitness. We also partner with OEMs who design innovative therapeutic devices and need a reliable electrode supply chain. Because we offer both private-label and custom manufacturing, our services are equally valuable to clinical distributors and consumer wellness brands.

How do you ensure consistency across large production runs?

Consistency starts with material sourcing. We carefully vet suppliers for conductive films, foams, adhesives, and substrates, ensuring repeatable properties. During production, we use advanced rotary die cutting and in-line inspection systems to maintain tight tolerances. Every batch undergoes documented quality checks to verify size, adhesion, conductivity, and durability. This combination of automated controls and human oversight minimizes defects and ensures predictable performance.

What if my company has intellectual property concerns?

Confidentiality is a top priority at Pepin Manufacturing. We sign non-disclosure agreements (NDAs) as needed and maintain secure design and production processes. Your proprietary specifications, artwork, and product designs are treated with strict confidentiality. We understand the competitive importance of intellectual property and work to safeguard your brand assets at every stage.

Start Your Next Electrotherapy Project With Us

At Pepin Manufacturing, we’re committed to delivering excellence in every electrode we produce. Our comprehensive manufacturing and services provide the foundation for long-lasting, high-performance electrotherapy products that meet both clinical and commercial expectations.

Contact us today online or by phone at 651.345.5655 to learn more about our capabilities and how we can support your next electrotherapy electrode production run.