Precision Slitting

Expert Precision Slitting for Custom Material Conversion

At Pepin Manufacturing, Inc. (PMI), we offer high-quality precision slitting services tailored to meet the strict requirements of industries ranging from medical and industrial to electronics and personal care. With an ISO-13485-certified facility located in Lake City, Minnesota, our team has the experience, technology, and attention to detail necessary to convert a wide range of flexible materials into precisely slit rolls for further processing, converting, or end use.

Whether you require ultra-narrow tolerances for diagnostic device components or high-speed slitting for large-scale production runs, PMI’s precision slitting services deliver the consistency, cleanliness, and accuracy that your application demands.

Request A Quote

Home » Contract Converting » Precision Slitting

What Are Precision Slitting Services?

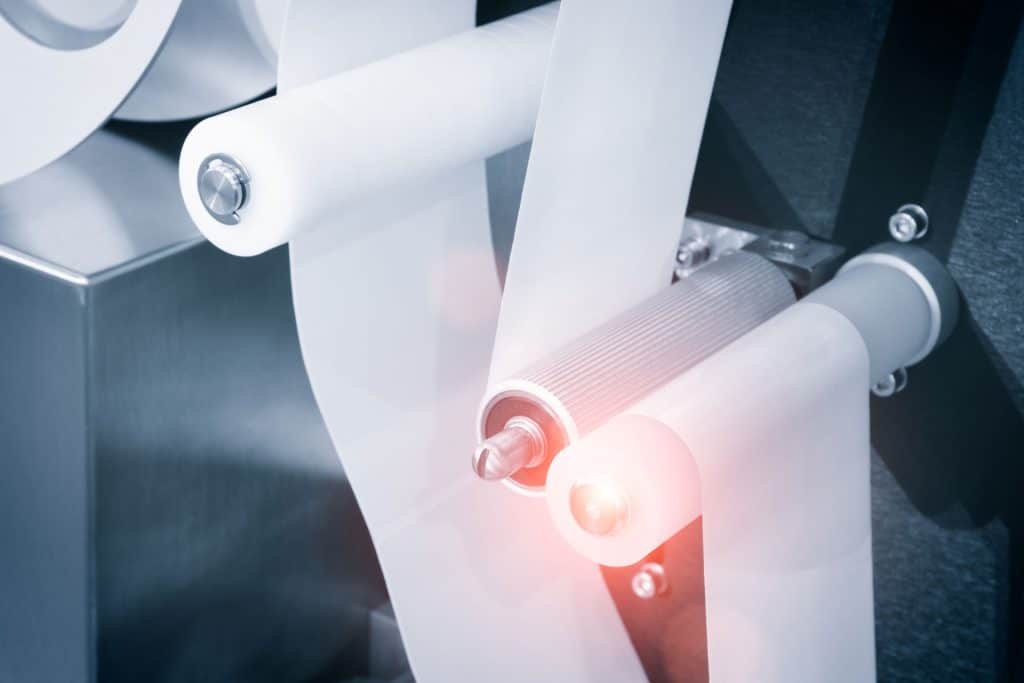

Precision slitting refers to the process of cutting wide rolls of flexible material into narrower widths using high-speed rotary or shear slitting equipment. This process is essential for preparing materials for downstream converting processes or for creating finished roll stock ready for distribution or assembly.

At PMI, our precision slitting services are optimized to handle various materials, including:

- Pressure-sensitive adhesives

- Medical-grade films and foils

- Nonwoven and woven fabrics

- Foams and laminates

- Hydrogels and coated substrates

- Release liners and barrier films

We can achieve extremely tight width tolerances while maintaining clean edges, minimizing dust, and preventing adhesive bleed or material deformation. This makes our slitting solutions ideal for applications where cleanliness and dimensional accuracy are critical.

Benefits of Choosing PMI’s Precision Slitting Services

Partnering with PMI for precision slitting provides you with more than just tight tolerances. It ensures that your materials are handled with the utmost care and converted to exact specifications with full quality oversight. From high-speed slitting to narrow-width micro rolls, we support both low-volume and large-scale production needs.

Key Benefits Include:

- Tight Tolerances: Consistently achieve accurate roll widths for demanding applications such as medical devices, diagnostics, or electronics.

- Material Versatility: We slit a wide range of materials, including adhesive-coated, multilayer, and delicate substrates.

- Clean Edges: Our advanced slitting technology ensures smooth, burr-free edges without material deformation or delamination.

- High-Speed Efficiency: Rapid throughput and efficient setups reduce lead times and improve manufacturing flexibility.

- Scalable Solutions: Whether you need short-run prototyping or full-scale production, our precision slitting capacity scales with your project.

- Regulatory Assurance: All slitting operations are performed under strict quality and regulatory protocols in our facility.

Our process ensures not just accurate slitting, but also preserves material integrity, allowing for optimal performance in subsequent processes such as die cutting, laminating, or packaging.

Industries We Serve With Precision Slitting Services

PMI’s precision slitting services are trusted by companies across a broad spectrum of industries. Our expertise, equipment, and regulatory capabilities make us the partner of choice for businesses seeking dependable material conversion for skin-contact products, diagnostic tools, industrial adhesives, and more.

Medical and Healthcare

- Slitting of adhesive rolls for wound care and securement

- Narrow roll stock for diagnostic and wearable devices

- Hydrogels for electrodes and skin-contact applications

- Barrier films for moisture-resistant medical packaging

Electronics and Industrial

- Dielectric films and insulation tapes for circuit assembly

- EMI shielding and conductive materials

- Industrial adhesives and mounting tapes

- Custom laminates for product assembly

Personal Care and Consumer Goods

- Foams, liners, and films for hygiene or cosmetic products

- Custom-laminated materials for transdermal patches

- Peel-and-stick applications for first-aid or household use

Integrated Capabilities to Complement Precision Slitting

Our precision slitting services are part of a fully integrated suite of converting capabilities designed to streamline your supply chain, improve product quality, and reduce time to market. Many of our slitting projects are combined with downstream processes such as die cutting, laminating, and packaging—all performed under one roof for maximum efficiency.

Integrated Capabilities:

- Rotary & Flat Bed Die Cutting: Further convert slit rolls into precision-cut parts, labels, or pads.

- Multi-Layer Lamination: Combine substrates before or after slitting to build custom constructions.

- Hydrogel Slitting: Custom hydrogel and precision slitting for electrode and medical applications.

- Contract Packaging & Assembly: Complete fulfillment of slit and converted materials, including roll rewinding, pouching, and labeling.

- Printing Services: Apply branding, usage instructions, or tracking codes on slit roll materials.

This vertically integrated approach reduces material handling, minimizes logistics costs, and simplifies the procurement process for customers with complex supply chain requirements.

Quality and Compliance in Every Slit Roll

As a trusted partner in regulated industries, PMI maintains rigorous quality standards for all precision slitting operations. From incoming material inspection to in-line monitoring and final QC verification, we follow structured quality protocols to ensure consistent results on every run.

Quality & Compliance Highlights:

- ISO 13485:2016-certified quality management system

- Full traceability of materials and finished products

- In-line inspection systems for width and edge quality

- Documentation and record-keeping compliant with medical and industrial regulations

Whether you’re producing parts for a Class II medical device or preparing custom roll stock for a critical industrial process, PMI provides the quality assurance necessary to meet your standards.

Customization and Flexibility for Unique Slitting Needs

At PMI, no two slitting jobs are exactly alike. We offer extensive customization options to tailor your precision slitting project to your unique product requirements, end-use applications, and production timelines.

Customization Options Include:

- Custom Slit Widths: From micro rolls under 0.250” wide to full-width master rolls

- Roll Core Sizes & Diameters: Support for 1”, 3”, and 6” cores with various roll OD options

- Slitting Methods: Razor, shear, or score slitting based on material properties

- Tension Control: Adjustable web tensioning for sensitive or stretchable substrates

- Packaging & Labeling: Private labeling, batch identification, and custom wrapping

Our engineering and production teams work closely with you to understand your specific challenges, offer recommendations, and deliver a slitting solution that integrates seamlessly into your workflow.

Why Choose PMI for Precision Slitting Services?

With decades of experience, advanced slitting equipment, and a customer-focused team, PMI is the ideal partner for companies seeking accurate, efficient, and dependable precision slitting services. We don’t just cut materials—we engineer smart solutions that align with your business objectives, compliance needs, and product performance goals.

What Sets PMI Apart:

- Decades of converting and material handling expertise

- Advanced slitting technologies and in-line inspection systems

- Medical-grade manufacturing standards and cleanroom compatibility

- Rapid turnaround with full traceability and documentation

- Full-service support from prototyping through production and packaging

Get Started With Precision Slitting Services at PMI

We’ve built a credible reputation throughout multiple industries by always working to meet or exceed the latest industry standards and certifications. View the PDF below to learn more, or contact us to discuss our precision slitting services, and manufacturing and material capabilities.

Ready to elevate your product or streamline your manufacturing process with high-accuracy precision slitting? Contact Pepin Manufacturing, Inc. today to discuss your material requirements, request a quote, or schedule a consultation with our technical team.