Die Cutting Services

Comprehensive Die Cutting Services for Custom Manufacturing Applications

At Pepin Manufacturing, Inc. (PMI) we have decades of experience and a reputation for innovation, PMI offers flexible die cutting services tailored to exact project specifications. Whether you need a medium or high-volume production job, we provide scalable solutions that align with your timeline and performance requirements.

Request A Quote

Home » Contract Converting » Die Cutting Services

What Are Die Cutting Services?

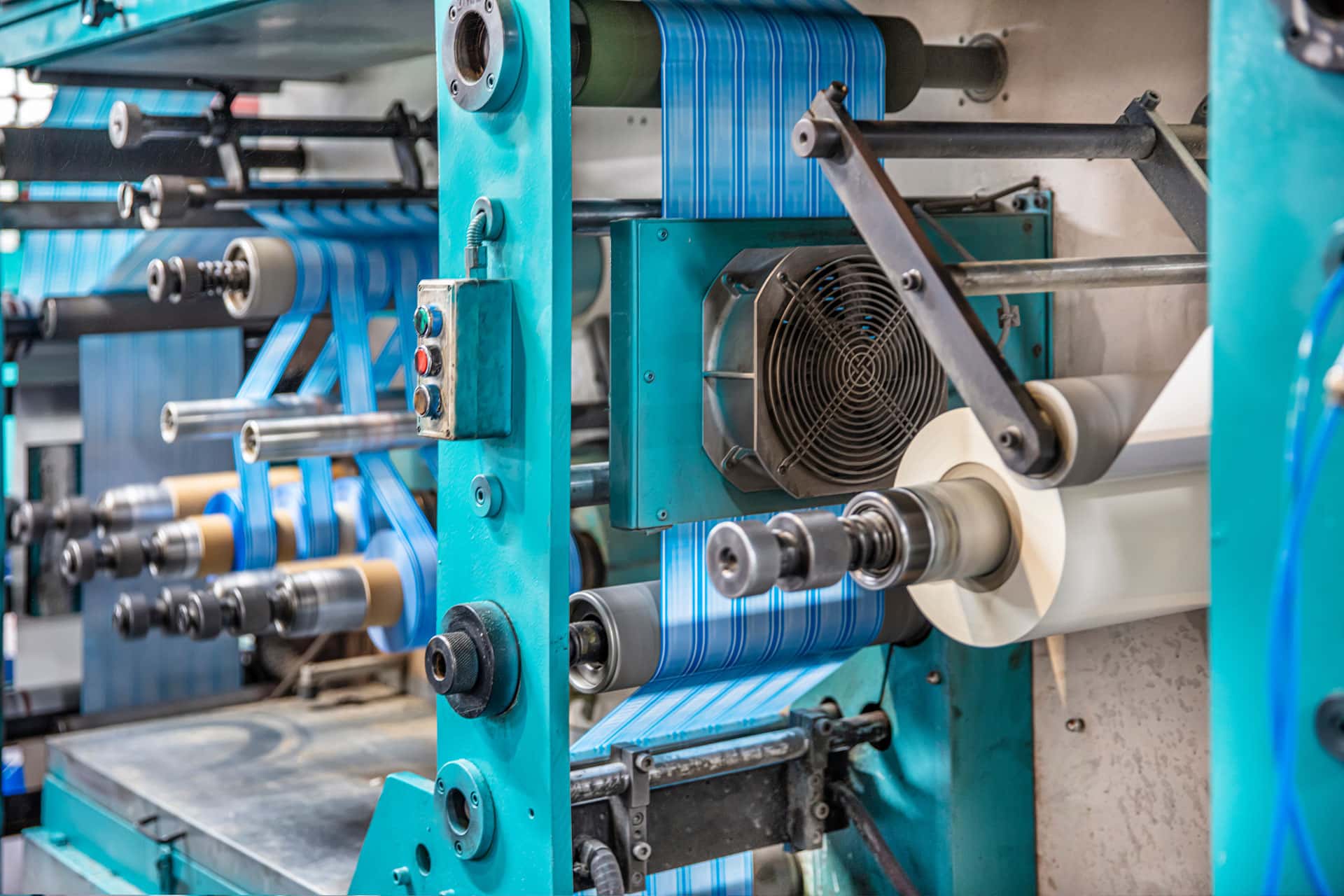

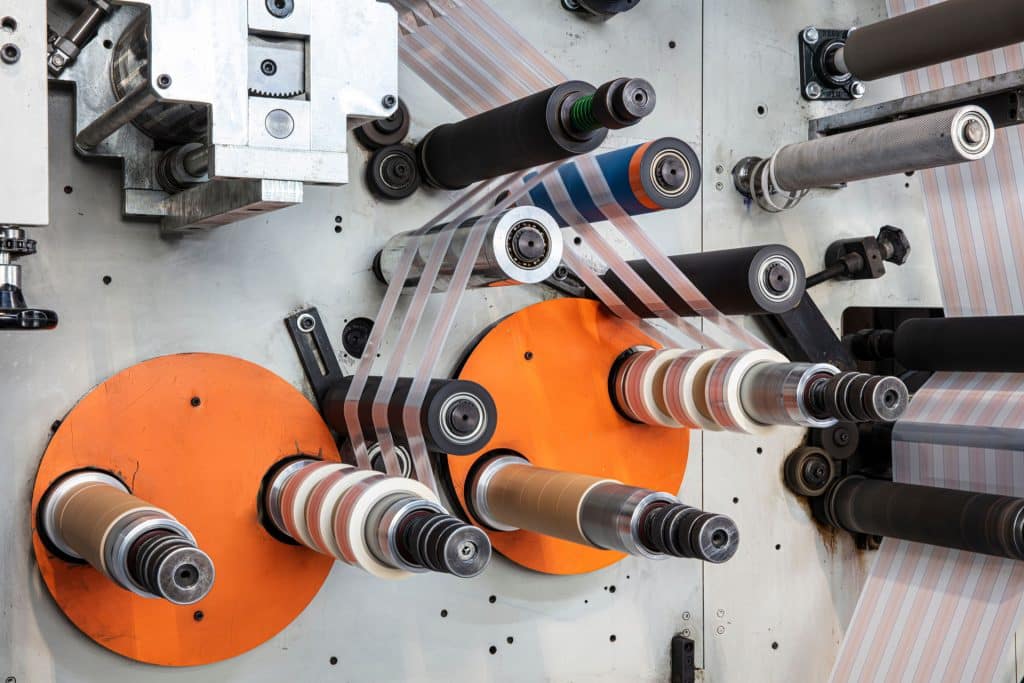

Die cutting services involve the use of a die—a specialized tool used to cut, shape, and form materials into a desired design. The process can be flatbed, rotary, or laser-based, depending on the materials involved and the complexity of the design. At PMI, we utilize a range of die cutting methods to ensure optimal results based on material type, tolerance requirements, and production volume.

Our die cutting services are ideal for converting flexible materials such as films, foams, adhesives, nonwovens, hydrogels, and specialty laminates into precise shapes for use in a variety of applications. From medical device components to industrial gaskets and retail packaging inserts, PMI delivers results that exceed expectations.

Advantages of PMI’s Die Cutting Services

Clients benefit from our die cutting services thanks to our deep industry knowledge and advanced equipment. Our services offer superior accuracy that ensures clean cuts and tight tolerances. The flexibility of our operations supports both custom and standardized formats, and our engineering team works closely with clients to assure it meets their specific application needs.

Our die cutting services are also optimized for efficiency, minimizing waste and driving down costs through smart material utilization and streamlined processes. Additionally, our capabilities allow for efficient transitions to full-scale production.

Industries We Serve With Die Cutting Services

Our die cutting services are engineered to meet the evolving needs of today’s manufacturers across a wide range of industries. From medical and industrial to aerospace, defense, cosmetic, and consumer goods sectors, our facility in Lake City, Minnesota, is equipped to deliver precision, consistency, and reliability at every stage of production.

Our die cutting services support a diverse range of industries with unique demands. In the medical field, we create critical components such as electrodes, wound dressings, diagnostic test strips, and device interfaces that require clean room-level precision. For industrial applications, we manufacture seals, insulation layers, and vibration-dampening elements built to endure tough conditions. In the aerospace and defense sectors, our die cut parts are trusted for their consistency and ability to meet rigorous quality standards.

Consumer brands rely on our die cutting services to produce items like adhesive patches, labels, beauty applicators, and custom packaging inserts that enhance both functionality and aesthetics. Whatever your field, PMI is prepared to develop a die cutting solution that supports your goals.

Custom Die Cutting Services With End-to-End Support

At PMI, die cutting services are never one-size-fits-all. Our process begins with understanding your specific application, performance goals, and production constraints. From there, we provide design consultation, tooling development, and material selection to ensure your product meets every requirement.

We offer full material sourcing support, drawing from a network of trusted suppliers to identify the ideal material for your needs. Our engineers help you evaluate factors like adhesion, compressibility, chemical resistance, and biocompatibility depending on your industry and product use case.

In addition to traditional die cutting services, we offer laminating, slitting, scoring, perforating, and inline printing to create multifunctional components that are ready for immediate integration or packaging. With value-added services like kitting and custom assembly, PMI delivers complete solutions under one roof.

Commitment to Quality and Compliance

Every product manufactured through our die cutting services is subject to stringent quality control protocols. As an ISO-13485 certified contract manufacturer, PMI is committed to maintaining the highest standards in documentation, traceability, and regulatory compliance. Our quality management system ensures that products not only meet but often exceed industry and client-specific standards.

Our in-house quality assurance team conducts regular inspections, monitors process controls, and validates every step of production. Whether you’re in a regulated field like medical devices or simply need reliable consistency for a consumer product, our die cutting services provide the assurance of dependable quality.

Frequently Asked Questions About Die Cutting Services

What materials can Pepin Manufacturing die cut?

PMI can die cut a wide variety of flexible materials, including foams, films, adhesives, nonwovens, hydrogels, laminates, rubber, paper, and specialty composites. Because of our extensive supplier network, we can also source specific materials tailored to your application requirements, such as biocompatible substrates for medical devices or heat-resistant films for industrial components.

How do I know which die-cutting method is right for my project?

The best die-cutting method depends on factors such as the type of material, thickness, tolerance requirements, and production volume. Flatbed die cutting works well for thicker materials and medium-volume jobs, while rotary die cutting is ideal for continuous high-volume runs with consistent precision. For intricate patterns or prototypes, laser die cutting can achieve clean, highly detailed cuts without the need for physical tooling. Our engineering team consults with you to recommend the most efficient and cost-effective option.

How does PMI ensure quality and consistency across large orders?

Our ISO-13485 certification means every product undergoes rigorous quality control processes. From first-article inspections to in-process checks and final validation, we document and verify every step. This level of traceability ensures consistent outcomes, whether we produce hundreds or millions of units.

What kind of tolerances can you achieve?

Tolerance levels depend on the material and cutting method, but PMI is equipped to achieve the tight tolerances required in industries such as aerospace, electronics, and medical devices. Our team works with you to establish the acceptable tolerance range for your application, ensuring the final product performs exactly as intended.

Can PMI provide multi-layer or laminated die-cut parts?

Yes. Many projects require laminating different materials to create multifunctional components. For example, we can laminate adhesives to foams, films to hydrogels, or multi-layer composites to meet specific performance requirements. In addition, we offer services such as slitting, scoring, and perforating to expand functionality.

What industries typically use PMI’s die-cutting services?

Our die-cutting solutions are applied across numerous sectors, including medical devices, industrial equipment, aerospace, defense, consumer products, cosmetics, and packaging. Each industry benefits from our ability to create precise, durable, and cost-effective components that meet demanding use conditions.

Can you provide assembly and kitting in addition to die cutting?

Yes. PMI offers value-added services such as assembly, packaging, and kitting to streamline your supply chain. By combining multiple components into a finished kit or ready-to-use product, we help reduce handling steps and improve efficiency for your business.

How long does it take to develop a custom die-cutting solution?

Timelines vary depending on the complexity of the project and tooling requirements. Simple projects with existing tooling may be completed quickly, while more advanced designs requiring new tooling or material validation may take longer. Our team communicates realistic lead times early in the process and offers expedited services when needed.

What makes PMI different from other die-cutting providers?

Pepin Manufacturing offers the precision, material versatility, and regulatory expertise that complex applications demand. With ISO 13485 certification, advanced registration and cutting systems, and in-house capabilities ranging from rotary and flatbed die-cutting to multi-layer lamination and cleanroom-ready assembly, PMI is built to support industries where accuracy and consistency are critical. Whether you’re developing a medical device, wearable sensor, or high-performance component, PMI delivers tight tolerances and responsive engineering support that sets us apart.

Contact Us for Expert Die Cutting Services

Let Pepin Manufacturing, Inc. be your trusted partner for precision die cutting services. Reach out to our team today to discuss your project, request a quote, or schedule a consultation with our engineering experts. Discover how our die cutting services can elevate your product performance and streamline your path to market success.

Why Choose PMI for Die Cutting Services?

Choosing PMI means choosing a partner who is committed to innovation, quality, and personalized service. We are problem solvers who thrive on challenges and take pride in developing manufacturing solutions that push the boundaries of what’s possible.

We work hand-in-hand with your team to understand your product’s functionality, end-use, and market requirements. Our responsiveness, flexibility, and technical expertise make us a trusted provider of die cutting services for clients across the country and beyond.

Whether you are developing a new product or scaling up an existing one, PMI offers die cutting services that deliver accuracy, efficiency, and exceptional value.