Flat Bed Die Cutting Services

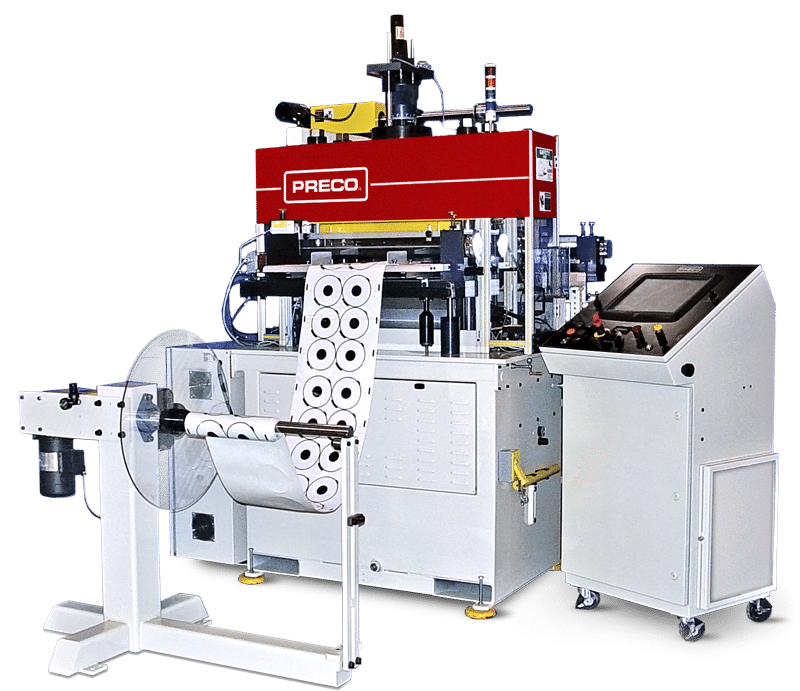

Whether your project is small volume or requires millions of parts, our 60-ton Preco flat bed die cutting press has the versatility to produce ultra-tight tolerance die cut parts using both sheet and rollstock, with quick tooling changeover.

Request A Quote

Home » Contract Converting » Die Cutting Services » Flat Bed Die Cutting

Precision Flat Bed Die Cutting Services for Custom Applications

At Pepin Manufacturing, Inc. (PMI), our flat bed die cutting services provide versatile, high-precision solutions for manufacturing custom components across a wide range of industries. Operating from our ISO-13485-certified facility in Lake City, Minnesota, PMI brings decades of expertise and a commitment to innovation to every project. Whether you’re producing medium batches or large-volume runs, our flat bed die cutting capabilities offer the flexibility, accuracy, and material compatibility you need.

What Are Flat Bed Die Cutting Services?

Flat bed die cutting is a precision manufacturing process that utilizes a hydraulic press and custom-shaped steel rule dies to convert sheet or rolled materials into specific shapes, sizes, and forms. Unlike rotary die cutting, which is best suited for continuous web processing, flat bed die cutting is ideal for producing parts with complex geometries, deeper cuts, or thicker materials. The process excels in projects that require lower volumes, tighter tolerances, or specialized cut features.

Our flat bed die cutting services are engineered to convert a wide range of flexible and semi-rigid materials, including:

- Foams

- Rubber

- Gaskets

- Nonwovens

- Medical-grade adhesives

- Laminated composites

- Thermoplastics

- Paper, films, and more

PMI’s flat bed die cutting systems are optimized for precision and repeatability, allowing us to manufacture complex parts with clean edges and tight dimensional control.

Benefits of Choosing PMI’s Flat Bed Die Cutting Services

When you choose PMI for your flat bed die cutting needs, you partner with a manufacturing team that prioritizes quality, efficiency, and tailored engineering support. Our in-house die design and fabrication capabilities allow us to deliver precision-crafted components that meet your exact specifications.

Key Benefits:

- Versatility: Flat bed die cutting accommodates a broader range of material thicknesses and densities, making it suitable for both rigid and compressible materials.

- Custom Die Engineering: Every die is manufactured to fit the part design and performance requirements of your application, enabling complex shapes and tight tolerances.

- Prototyping to Production: From small-scale pilot runs to full production volumes, we offer flexible scaling options to meet your needs at any development stage.

- Low Tooling Costs: Compared to other cutting methods, flat bed die cutting often provides cost-effective tooling, especially for short-run projects or evolving designs.

- Clean, Accurate Cuts: Our advanced press systems apply uniform pressure across the die surface, ensuring precise and consistent cuts with minimal material distortion.

Hear It from Our Clients

“Pepin was recommended to us by another manufacturing plant due to their expertise and experience with converting. We brought a complicated problem that many other converters have not been able to figure out and Pepin and their team have invested into this project even without promising results right away and they were able to perform the task. After a few runs, Pepin’s team spent ample hours collaborating and brainstorming some ideas and came up with a solution. SOSCO is so thankful for the relationship we have built with Pepin and continue to build. I also think the F-35 Fighter Jet team appreciates them as well!”

– Maci Pieper, Director of Operations at Sosco

Industries We Serve With Flat Bed Die Cutting

Medical and Healthcare

- Diagnostic test components

- Wound dressings and pads

- Electrodes and sensor assemblies

- Sterile barrier materials

Industrial and OEM

- Gaskets, washers, and seals

- Vibration-dampening pads

- Thermal insulation layers

- EMI/RFI shielding materials

Consumer and Retail

- Custom labels and decals

- Packaging inserts and protective liners

- Cosmetic application pads

- Point-of-sale components

Automotive and Aerospace

- Noise, vibration, and harshness (NVH) components

- Multi-layer insulation pads

- Engine compartment gaskets

Dielectric insulation films

Tailored Flat Bed Die Cutting Solutions

No two projects are alike, and that’s why our flat bed die cutting services are fully customizable to your product’s unique needs. We offer a wide range of die cutting techniques and inline processes, including:

- Kiss cutting for peel-and-stick components

- Perforating for breathability or tear features

- Creasing and scoring for folding applications

- Multi-layer laminating and stacking

- Registration cutting for print-to-cut alignment

PMI works closely with your engineering, R&D, or procurement teams to design and deliver parts that perform reliably in real-world conditions. Whether you’re developing a single-use medical product or a durable gasket for an industrial machine, we provide a manufacturing strategy that aligns with your performance goals and budget.

Integrated Capabilities for a Complete Manufacturing Solution

At PMI, our flat bed die cutting services are just one part of our broader contract manufacturing capabilities. We offer an integrated suite of services designed to streamline your supply chain and accelerate your time to market.

Additional Capabilities Include:

- Material Sourcing & Sampling – PMI helps you select the best materials for your application from a wide network of trusted suppliers.

- Laminating & Slitting – Convert multi-layer materials or prepare material rolls to exact widths before die cutting.

- Custom Printing – Add branding, batch information, or regulatory labels to your die-cut components.

- Kitting & Assembly – We can assemble components, apply adhesives, or create ready-to-use kits tailored to your workflow.

These value-added services enhance the quality and functionality of your final product while simplifying your logistics and procurement process.

Quality and Compliance You Can Trust

As an ISO-13485-certified manufacturer, PMI upholds rigorous quality assurance standards throughout every step of our flat bed die cutting services. Our quality team monitors production from material inspection to final testing, ensuring each component meets performance, regulatory, and documentation requirements.

- Full material traceability

- Documented process validation

- Batch control and statistical process monitoring

- Compliance with customer-specific requirements and global standards

Our commitment to quality gives clients peace of mind, whether you’re manufacturing Class I medical devices, safety-critical automotive parts, or high-performance industrial components.

Tailored Flat Bed Die Cutting Solutions

No two projects are alike, and that’s why our flat bed die cutting services are fully customizable to your product’s unique needs. We offer a wide range of die cutting techniques and inline processes, including:

- Kiss cutting for peel-and-stick components

- Perforating for breathability or tear features

- Creasing and scoring for folding applications

- Multi-layer laminating and stacking

- Registration cutting for print-to-cut alignment

PMI works closely with your engineering or procurement teams to deliver parts that perform reliably in real-world conditions. Whether you’re developing a single-use medical product or a durable gasket for an industrial machine, we provide a manufacturing strategy that aligns with your performance goals and budget.

Get Started With PMI’s Flat Bed Die Cutting Services Today

Looking to bring precision, efficiency, and customization to your next manufacturing project? Contact the experts at Pepin Manufacturing, Inc. to learn how our flat bed die cutting services can help you meet your production goals.

Request a quote, schedule a consultation with our technical team to get started. Let PMI show you how our flat bed die cutting solutions can enhance product quality and reduce production costs.

Why Choose PMI for Flat Bed Die Cutting Services?

With decades of manufacturing experience and a strong foundation in process innovation, PMI is a trusted partner for businesses that demand precision, reliability, and responsive support. When you choose us for flat bed die cutting services, you’re not just hiring a supplier—you’re gaining a strategic partner committed to your product’s success.

- Proven experience across regulated and high-performance markets

- Custom solutions tailored to your specifications

- State-of-the-art equipment and tooling

- Transparent communication and collaborative project management

- Scalable capabilities from prototypes to full production