Precision makes all the difference when it comes to delivering top-quality materials and components. At Pepin Manufacturing, our rotary die-cutting services demonstrate how precision and innovation can be combined to produce exceptional results. The accuracy we provide ensures that every product, whether it be custom gaskets, adhesives, or medical components, meets the highest standards. Here is why precision matters in rotary die-cutting.

What Is Rotary Die-Cutting?

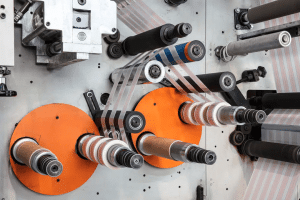

Rotary die-cutting is a highly versatile and efficient process for cutting, shaping, and creating intricate designs out of a wide variety of materials. It uses cylindrical dies and a rotary press to produce precise cuts quickly and consistently.

This method is valued for its speed, repeatability, and adaptability to different industries. From medical devices to industrial parts, rotary die-cutting delivers custom solutions tailored to exact specifications. At Pepin Manufacturing, this technology is crucial to meeting the unique needs of our clients.

The Critical Role of Precision

Precision in rotary die-cutting isn’t just a nice-to-have; it’s an absolute must. Every cut, every dimension, and every material alignment plays a role in how a final product functions. A tiny error in a component can lead to big consequences, especially in industries like healthcare or electronics, where performance matters most.

For instance, custom medical devices often require components with zero room for error. A misaligned cut could compromise product performance, safety, or regulatory compliance. Precision solves this problem, ensuring every product meets stringent requirements—both yours and ours.

Why Does Precision Matter?

Here are some key reasons precision in rotary die-cutting is non-negotiable:

- Consistent Quality: Precision ensures every product in a production batch matches specifications, reducing variability.

- Improved Functionality: An accurate cut leads to better product performance, whether it’s a gasket, filter, or medical adhesive.

- Material Efficiency: With precise cuts, there’s less material waste, saving you time and money.

- Regulatory Compliance: Industries like healthcare or aerospace demand precise components to meet strict standards.

- Brand Reputation: A high-quality product results in satisfied customers and a stronger reputation for your business.

At Pepin Manufacturing, we take these factors seriously. Our technology and expertise are designed to deliver exceptional results, no matter your industry.

How Pepin Manufacturing Ensures Precision

We understand that perfection isn’t just about machines—it’s about the people using them, the materials chosen, and the processes followed. Here’s how Pepin Manufacturing ensures precision in rotary die-cutting for every project.

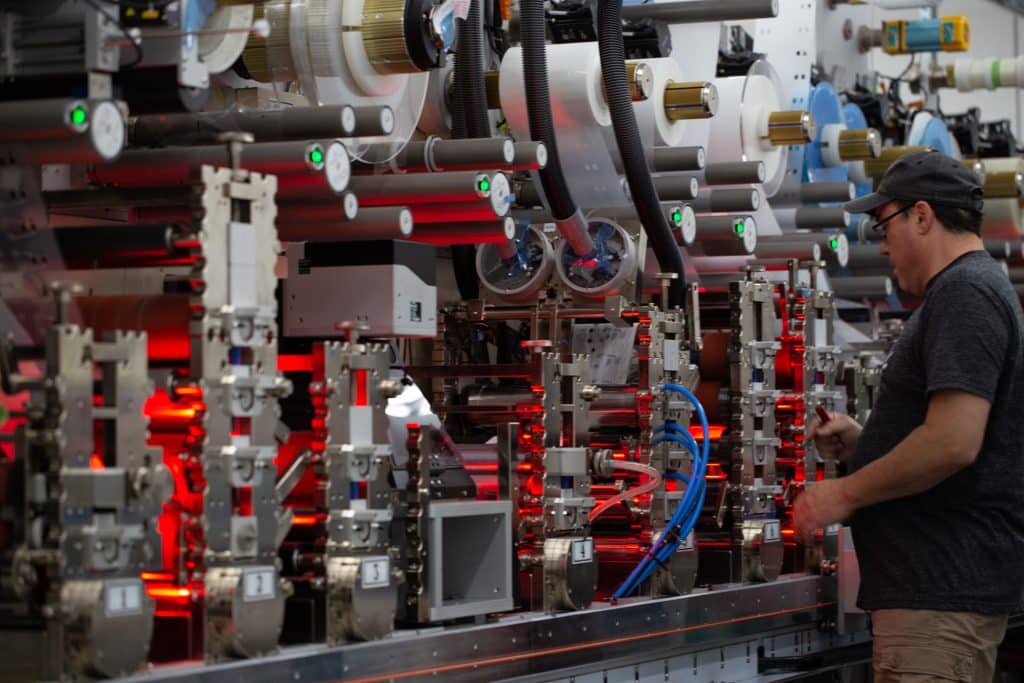

Advanced Equipment

Rotary die-cutting relies heavily on advanced engineering, and so do we. At Pepin Manufacturing, our state-of-the-art equipment supports tight tolerances and delivers consistent results.

- Modern rotary die presses keep cuts clean and exact.

- Features like automated registration systems ensure every cut aligns perfectly.

- Equipment can handle various materials, including foam, medical-grade adhesives, and thin films.

Expert Staff

Even the best machines need skilled operators to maximize their potential. Our experienced team works alongside cutting-edge technology to guarantee precision. From planning the die design to inspecting the final output, our staff is committed to getting it right the first time—and every time after that.

Custom Solutions for Unique Needs

Precision isn’t one-size-fits-all. Each industry and application has its own standards. That’s why Pepin Manufacturing tailors each job to meet specific requirements. Whether it’s tight die tolerances for electronics or cleanroom standards for medical components, we adapt our processes for you.

Quality Control

Precision relies on robust quality control processes. At Pepin Manufacturing, we perform thorough inspections at every stage of production. Our quality assurance protocols are designed to identify and correct even the smallest discrepancies, ensuring you get exactly what you ordered.

Precision Across Industries

Rotary die-cutting is used across a diverse range of industries, and in all of them, precision is a key factor for success.

Medical Industry

Adhesive tapes, wound care materials, and other medical components often come with tight tolerance requirements. Precision ensures these products perform exactly as intended while meeting strict FDA regulations.

Electronics

From custom insulation to conductive tapes, electronics require components with pinpoint accuracy. Any deviation in size or shape could compromise a device’s performance.

Industrial Applications

Gaskets, seals, and protective materials often bear high-pressure environments. Precision in manufacturing ensures reliability and durability when it matters most.

For these industries and more, Pepin Manufacturing uses rotary die-cutting to provide tailored solutions that meet the highest performance and safety standards.

The Benefits of Partnering with Pepin Manufacturing

When you work with Pepin Manufacturing, you gain more than just a service provider; you get a dedicated partner in precision production. Here’s what sets us apart.

Wide Range of Materials

We work with an extensive selection of materials to meet unique customer needs, including pressure-sensitive adhesives, thin plastics, foams, and nonwoven fabrics. No matter your application, we have the flexibility to match it.

Customization

We excel at creating custom rotary die-cutting solutions—from developing specialized dies to producing parts that meet exacting specifications.

Longevity and Experience

With decades of expertise, Pepin Manufacturing has the knowledge to solve even the most complex die-cutting challenges.

Reliable Delivery

A quick turnaround matters, and so does meeting your production timelines. Our streamlined processes ensure your products are delivered on schedule without compromising quality.

Customer-Centric Approach

Your goals are our goals. We work closely with our clients to ensure the final product not only meets expectations but exceeds them.

Why Trust Pepin Manufacturing?

When precision is a priority, Pepin Manufacturing is the partner you can trust. We combine cutting-edge technology, skilled craftsmanship, and a commitment to quality to deliver industry-leading results in rotary die-cutting.

From concept to completion, we treat every project as if it were our own. With years of experience and an unwavering focus on customer satisfaction, we’re here to make your vision a reality.

Explore Precision Rotary Die Cutting Services

Precision in rotary die-cutting isn’t just about getting cuts right—it’s about ensuring your products perform as they should. At Pepin Manufacturing, we understand that attention to detail makes all the difference.

When you choose our die-cutting services, you’re investing in quality, reliability, and a partner who prioritizes your needs. Whatever your industry or application, trust Pepin Manufacturing to deliver precise, efficient, and customized die-cutting solutions.

Interested in learning more? Reach out to our team today to discuss how our rotary die-cutting services can help bring your vision to life!