At Pepin Manufacturing, we’re constantly amazed by the wide range of innovations our clients bring to life using our high-volume rotary die cutting services. It’s a process that might seem behind the scenes, but its impact is felt everywhere, from the medical devices that save lives to the protective films in your car and the electronic components in your gadgets. Essentially, anywhere you need a large quantity of precise, identically-shaped parts from a flexible material, rotary die cutting services are likely the answer.

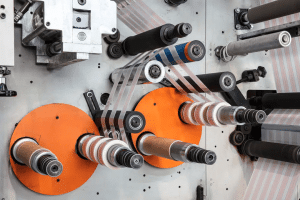

At its core, rotary die cutting is a high-speed converting process that uses a cylindrical die to cut shapes out of a roll of material as it passes through a press. The cylindrical nature of the die allows for continuous motion and incredible speeds, making it the go-to method for large-scale production. This isn’t just about cutting—it’s about accuracy, repeatability, and efficiency. For industries where precision and volume are non-negotiable, it’s an indispensable tool.

The Medical & Healthcare Industry

The healthcare industry operates on a foundation of precision and reliability. When it comes to manufacturing medical devices, wound care products, and diagnostic components, there is zero room for error. This is where high-volume rotary die cutting services become a lifesaver.

Wound Care Dressings and Adhesives

Think about a bandage. It’s a simple product, but it requires multiple layers cut to exact specifications. Rotary die cutting allows for the precise lamination of a breathable backing, an absorbent pad, and a medical-grade adhesive, all in one pass. It ensures that every single dressing is identical, providing consistent performance and patient comfort.

Wearable Medical Devices

Wearable technology for health monitoring, such as heart rate sensors or glucose monitors, relies on custom-shaped adhesive components. These devices need to adhere securely to the skin while remaining comfortable and non-irritating. The accuracy of rotary die cutting ensures that the adhesive shape perfectly matches the device’s design, guaranteeing a proper fit and function.

Surgical and Diagnostic Test Strips

From blood glucose tests to pregnancy kits, diagnostic strips are often multi-layered products with microfluidic channels and reagent pads. These intricate components are cut with incredible precision using rotary dies to ensure accurate results. The high-speed nature of the process allows for the mass production needed to meet global healthcare demands.

The ability to create high-precision, multi-layered components at scale, while using medical-grade materials like hydrogels, foams, and specialty tapes, is why so many medical companies turn to rotary die cutting services. It’s not just about manufacturing—it’s about enabling life-changing technology.

Automotive & Aerospace

In the automotive and aerospace sectors, every component must be manufactured to tight tolerances to ensure safety and performance. Rotary die cutting is instrumental in creating a vast array of parts that may not be visible but are critical to a vehicle’s function.

Automotive Gaskets and Seals

Under the hood, gaskets and seals prevent leaks and protect against heat, moisture, and vibration. These parts are often made from materials like foam, rubber, and specialty films. A single model of a car requires tens, if not hundreds, of different gasket shapes. The high-volume efficiency of rotary die cutting services is essential for producing these components consistently and cost-effectively for mass-produced vehicles.

Interior and Exterior Films

From protective films on dashboards and screens to sound-dampening insulation under the carpet, die-cut parts are everywhere in a car’s interior. Rotary die cutting can precisely cut and laminate these materials, ensuring a perfect fit and finish.

Aerospace Components

The aerospace industry demands materials that can withstand extreme environments. Rotary die cutting is used to produce precision-cut components from highly conductive films, heat shields, and adhesive parts used in everything from seating to navigation systems. The process’s ability to maintain tight tolerances and full traceability makes it a trusted partner for defense and aerospace manufacturers.

By providing a scalable and highly accurate method for producing complex components, rotary die cutting services help vehicle and aircraft manufacturers maintain the highest standards of quality and safety.

The Electronics Industry

When you look at the inside of an electronic device, whether it’s a smartphone, a laptop, or an appliance, you’ll find dozens of small, custom-cut components that are vital to its functionality. The tiny gaskets, insulation pads, and thermal management layers that protect sensitive circuits are often produced using high-volume rotary die cutting services.

EMI/RFI Shielding Gaskets

Electromagnetic and radio frequency interference can disrupt an electronic device’s performance. Rotary die cutting is used to create gaskets from conductive foils and foams that shield sensitive components, ensuring clear signals and reliable operation.

Thermal Management

Components that manage heat, like thermal pads and heat sinks, need to be cut to precise shapes to fit within a device’s compact design. Rotary die cutting allows for the clean, accurate cuts needed to produce these critical parts in massive quantities.

Protective Films and Adhesives

From screen protectors to multi-layered adhesive tapes that hold internal parts in place, die-cut films are a staple of electronics manufacturing. The process ensures that each piece is perfectly sized for seamless assembly and performance.

The need for miniature, high-tolerance components in a market driven by rapid innovation and short product lifecycles makes rotary die cutting services an essential part of the electronics supply chain.

Packaging & Consumer Goods

The packaging industry relies on die cutting for everything from product labels and stickers to blister packs and food packaging. While flatbed die cutting is often used for boxes and other larger items, rotary die cutting services are a perfect fit for high-volume, high-speed applications.

Custom Labels and Decals

Whether it’s a product label with an intricate shape or a custom sticker, rotary die cutting can kiss-cut the top layer while leaving the backing intact, enabling fast and easy peeling. This process is essential for producing millions of identical labels for everything from beverage bottles to cosmetic containers.

Flexible Packaging

From pouches to sachets, flexible packaging often requires perforations, tear lines, and seals. Rotary die cutting can perform all of these functions in an in-line process, creating a ready-to-fill package with consistent and reliable features.

Point-of-Sale Displays

While often overlooked, the custom-shaped pieces that make up retail displays and promotional materials are often die-cut. The process allows for the creation of eye-catching designs at a speed that supports aggressive marketing timelines.

By providing a rapid and cost-effective way to create complex shapes and features, rotary die cutting services help consumer brands differentiate their products and streamline their production lines.

The Pepin Manufacturing Difference for Rotary Die Cutting Services

At Pepin Manufacturing, we understand that precision is paramount. As an ISO-13485 certified facility with high standards, we are equipped to handle complex projects that demand the highest level of accuracy and consistency. Our team has the expertise to work with a vast array of materials, from thin films and tapes to foams and nonwovens, and to customize a solution that meets your unique project needs.

Choosing a partner for your rotary die cutting services is about more than just finding a manufacturer; it’s about finding a partner committed to your success. Our custom-engineered dies, streamlined processes, and integrated capabilities, such as laminating, slitting, and printing—ensure that we don’t just deliver a part, we deliver a complete solution. We focus on hands-on support, in-depth technical expertise, and responsive communication, making us a trusted partner for companies that need precision, durability, and value.

Whether you’re in the medical, automotive, electronics, or consumer goods industry, let’s discuss how our capabilities can help you achieve your manufacturing goals.

Contact us today to learn how our high-volume rotary die cutting services can elevate your product performance and streamline your path to market success.