Choosing the right manufacturing partner impacts every aspect of your business. From product quality to delivery timelines, the partner you select determines whether your production runs smoothly or becomes a constant source of stress and unexpected costs.

When you’re committing to a long-term production relationship, reliability isn’t just a nice feature. It’s the foundation that allows you to scale confidently, meet customer demands consistently, and focus on growing your business instead of managing manufacturing crises.

Consistent Quality Standards Across Every Run

Your customers expect the same high-quality product every single time. A reliable manufacturing partner delivers that consistency, whether it’s your first order or your thousandth.

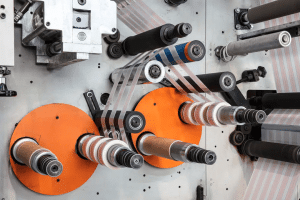

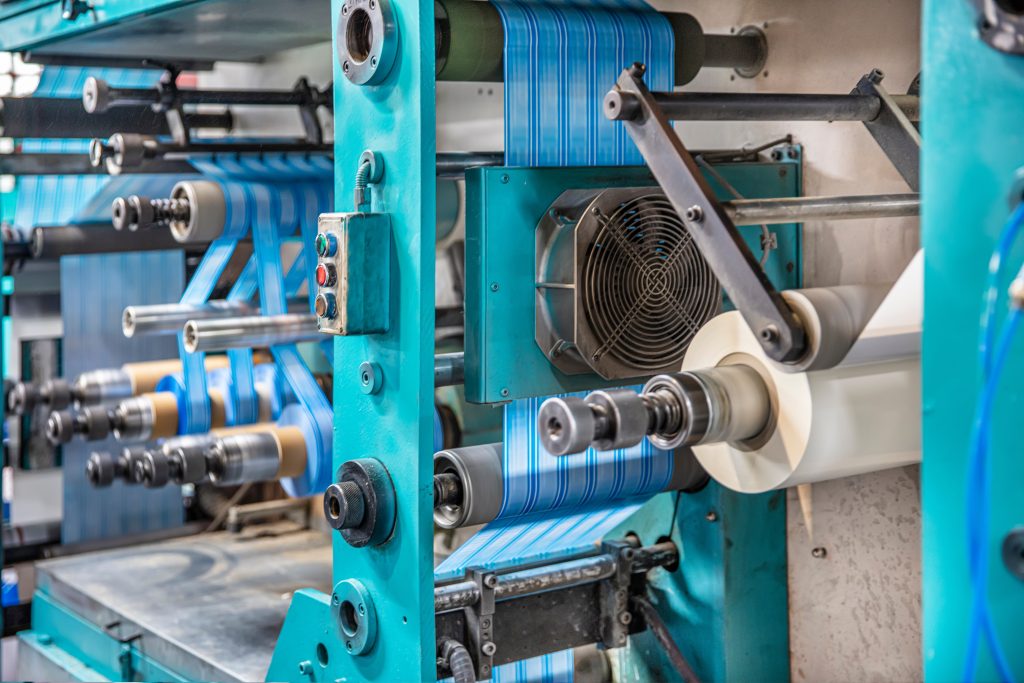

This consistency comes from rigorous quality control processes, advanced equipment maintained to exacting standards, and skilled technicians who understand that precision matters. When your manufacturing partner maintains tight tolerances and documented quality procedures, you eliminate the costly variations that damage your reputation and waste your resources.

Look for partners who can demonstrate their quality management systems. ISO certifications, documented inspection protocols, and statistical process controls all indicate a commitment to delivering identical results batch after batch. Your production shouldn’t be a gamble. It should be a predictable, reliable process that you can build your business on.

Technical Expertise That Solves Your Challenges

Manufacturing challenges don’t follow a script. You need a partner who brings deep technical knowledge and problem-solving capabilities to your projects.

The best manufacturing providers employ experienced engineers and technicians who understand materials, processes, and applications. This expertise becomes invaluable when you’re developing new products or scaling existing ones. A knowledgeable partner helps you:

- Select the right materials for your application

- Optimize designs for manufacturability

- Reduce waste and improve efficiency

- Navigate complex technical requirements

- Troubleshoot issues quickly when they arise

Technical expertise turns your manufacturing supplier into a strategic asset rather than just a service provider.

Advanced Capabilities That Grow With Your Needs

Your production requirements evolve as your business grows. A reliable long-term partner offers the capabilities and capacity to scale alongside you.

Multiple manufacturing processes under one roof simplify your supply chain and reduce coordination issues. When a single partner handles rotary and flatbed die-cutting, precision cutting, and contract packaging, you work with fewer vendors and smoother logistics.

Advanced equipment is just as important. Precision machinery that maintains tight tolerances ensures consistent quality, faster turnaround times, and the ability to support more complex projects.

Responsive Communication That Keeps You Informed

Production delays and material shortages happen. What separates reliable manufacturing partners is how they respond.

A strong partner communicates early, answers questions quickly, and involves knowledgeable teams who understand both your requirements and their processes. This level of responsiveness supports day-to-day collaboration, continuous improvement, and fewer issues over time, without the need for constant oversight.

Proven Track Record in Your Industry

Experience matters in manufacturing. A partner who has worked extensively in your industry understands the specific challenges, regulations, and performance requirements your products must meet.

Industry experience translates into practical advantages. Your manufacturing partner anticipates the issues specific to your applications. They know which materials perform best in your conditions. They understand the compliance requirements and quality standards your industry demands.

This background knowledge accelerates project timelines and reduces the learning curve on new initiatives. Instead of educating your manufacturing partner about industry basics, you collaborate with experts who already speak your language and understand your constraints.

Flexibility That Adapts to Your Production Cycles

Business isn’t static. Your production volumes fluctuate with demand, seasons, and market conditions. A reliable long-term partner accommodates these changes without compromising quality or inflating costs unreasonably.

Manufacturing flexibility shows up in multiple ways:

- Ability to do large production runs and small custom orders

- Willingness to adjust schedules when your priorities shift

- Capacity to scale up quickly when demand surges

- Understanding when rush orders are urgent versus routine requests

Partners who demonstrate this flexibility become true collaborators in your success. They work with you through the ups and downs of business cycles rather than treating every deviation from the plan as an inconvenience.

Transparent Pricing With No Hidden Surprises

Long-term manufacturing relationships require financial predictability. You need to understand what you’re paying for and why, with pricing structures that remain fair and consistent over time.

Reliable partners provide detailed quotes that break down costs clearly. They explain price variations when materials, complexity, or specifications change. Most importantly, they don’t surprise you with unexpected charges or vague “additional fees” that appear on invoices.

This transparency builds trust and allows you to forecast costs accurately. When your manufacturing partner prices honestly and explains changes clearly, you can plan budgets, set product prices, and make informed business decisions.

Investment in Specialized Solutions

Some applications require specialized expertise and custom solutions. Long-term manufacturing partners invest in these capabilities instead of relying on one-size-fits-all processes.

Capabilities like custom urethane formulations or precision electrode manufacturing require deep materials knowledge, refined processes, and strong quality systems. When a partner has made these investments, it signals a long-term commitment to serving your industry, not short-term project wins.

End-to-End Service That Simplifies Your Operations

Managing multiple vendors adds complexity, delays, and more chances for things to go wrong. A manufacturing partner with end-to-end capabilities simplifies your supply chain.

When one team handles everything from die-cutting through final packaging, you eliminate vendor handoffs, reduce shipping, and maintain consistent quality. The result is lower costs, faster lead times, and fewer errors, so you can focus on running your business instead of managing vendors.

Build Your Long-Term Partnership

At Pepin Manufacturing, we’ve spent over three decades building our reputation as a reliable manufacturing partner. Our expertise in rotary die-cutting, flatbed die-cutting, precision cutting, and contract packaging gives you the comprehensive capabilities you need under one roof.

Contact our team today to discuss your project requirements. Let’s explore how our expert services can support your long-term production needs with the reliability and quality your business demands.