Ever had your end user get a sudden, sharp jolt from a TENS unit? Or maybe you’ve dealt with the frustrating feedback of electrodes peeling off mid-session, ruining your company’s reputation? These aren’t minor annoyances. For any company in the business of electrotherapy, these failures are a direct reflection on your product. The electrotherapy electrode is the single point of contact between your technology and your customer. When it fails, your entire brand image takes a hit. We get it, because we’ve spent over 30 years helping companies like yours perfect this one critical component. At Pepin Manufacturing, Inc. (PMI), our goal is simple: make an electrode so reliable, so comfortable, that it disappears into the background, allowing your device to truly shine.

Why the Patient Experience Is Everything

The patient experience is the foundation of a successful product. If a TENS or EMS device is supposed to provide relief, but a poor-quality electrode causes discomfort or inconsistency, it defeats the whole purpose. Patients will stop using the device, and you’ll lose a customer. They won’t just blame the electrode; they’ll blame your entire product.

The True Cost of a Bad Electrode

A poorly made electrode can lead to inconsistent current, causing “hot spots”—those uncomfortable, tiny electric pinpricks that can make a user jump. Our high-quality electrodes, on the other hand, are engineered for uniform current dispersion, which means the sensation is consistently smooth and comfortable across the entire pad. That simple difference can be the deciding factor in whether a patient sticks with their therapy or gives up. It’s about building trust in your product and empowering them to feel confident in their ability to manage their pain or condition.

A quality electrode also needs to last. When a pad loses its stickiness after only a few uses, it’s not just an inconvenience for the patient; it’s a waste of money for them and a blow to your reputation. We design our electrodes for improved reusability, ensuring they maintain their adhesion and conductivity through repeated use.

The Science Behind a Comfortable Electrode

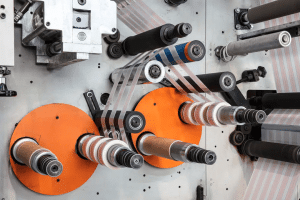

The secret to a superior electrotherapy electrode isn’t complicated. It’s about a relentless focus on quality and precision. We don’t just slap a few layers together; we engineer every component to work in harmony for optimal performance and patient comfort. Our decades of experience in precision converting and lamination allow us to expertly handle every detail, from the conductive carbon films to the medical-grade adhesives, with total mastery.

Our electrodes are built using a meticulous, multi-layer lamination process that ensures a consistent, high-performance product every time. Here’s what makes them different:

- Ultra-Low Impedance: This technical term just means our electrodes allow for an incredibly efficient connection. The signal travels from the device to the patient with minimal resistance, which improves the therapy’s effectiveness, patient comfort, and helps save device battery life. You get a strong, reliable signal from the very first moment of use, session after session.

- Precision-Engineered Components: We source and integrate a wide range of specialized materials, including conductive films, carbon-based substrates, and medical-grade nonwovens. Every single layer is carefully chosen and precisely aligned to meet the highest standards for conductivity and durability. This meticulous process is a key reason our products perform so well under various conditions.

- Consistent Hydrogel Placement: The hydrogel is what makes the pad stick and conduct. We use automated processes for precise placement, guaranteeing that every electrode has the same reliable grip and comfortable feel. This attention to detail on the part a patient touches every single day is crucial for a positive user experience.

This level of detail means that every product we manufacture is repeatable, reliable, and ready to perform. We’ve automated our processes to deliver this consistency, ensuring that the last electrode in a production run is just as perfect as the first. Our automated, USA-based manufacturing not only maintains quality but also allows us to offer competitive pricing by reducing labor costs and improving efficiency.

More Than Just a Manufacturer: A Real Partner

We provide comprehensive, end-to-end manufacturing and services that simplify your supply chain and let you focus on what you do best. Think of us as a single-source partner, cutting down the complexity of dealing with multiple vendors and giving you complete supply chain confidence.

We don’t just make things; we collaborate. Our team works with you to adapt designs, source materials, and scale production to meet your specific needs. This flexibility means we can support everything from small-scale test runs to high-volume, national rollouts. Our decades of experience across multiple industries give us unique insights into what works best for a wide range of applications, from clinical therapy to athletic training.

Our capabilities are extensive, covering everything from precision rotary die cutting to custom lead wire attachment, printing, and branding. We also offer private-label services, including custom print layouts, branded packaging, and instructional inserts. We help you create a finished product that stands out and gets noticed. Our goal is to make your product launch as smooth and stress-free as possible.

Quality Assurance: Protecting Your Brand

In the medical device industry, quality control isn’t an option. It’s everything. Your brand’s reputation and your product’s regulatory compliance depend on it. That’s why our manufacturing and services are built on rigorous quality protocols and a commitment to international standards. Our entire production process is managed with meticulous documentation and control systems that support full traceability, ensuring that every batch can be tracked and verified.

We align our processes with key quality and safety standards like ANSI and ASTM. Every step, from material handling in a controlled environment to in-line inspection and automated defect detection, is subject to a careful inspection.

Ready to Elevate Your Electrotherapy Electrode?

A great product deserves a great partner. If you’re ready to move past the headaches of inconsistent quality and unreliable production, it’s time to talk to us. Our comprehensive electrode manufacturing services provide the foundation for high-performance electrotherapy products that meet both clinical and commercial expectations.

Let’s build a product that your customers will love and that you can be proud to put your name on. Contact us online or by phone at (651) 345-5655 to learn more about our capabilities and how we can support your next electrotherapy electrode production run.