In contract manufacturing, almost every great product starts its life as a “master roll.” This is the large, wide roll of material that comes directly from the mill. It could be a 60-inch-wide roll of advanced adhesive, a 48-inch roll of medical-grade foam, or a 54-inch roll of high-performance film. While these master rolls are the source of innovation, they are completely unusable in their raw form for an automated assembly line or a rotary die-cutting press.

This is where a critical, and often overlooked, process comes in: precision slitting. This is the vital first step that converts those massive, unwieldy master rolls into perfectly sized, custom-width rolls that are optimized for your next manufacturing step. But this process is so much more than just “cutting.” This post will explore how precision slitting works, why the method matters, and how it unlocks the full potential of your material, from the most delicate films to the most robust foams.

What Is Precision Slitting, and Why Is It So Critical?

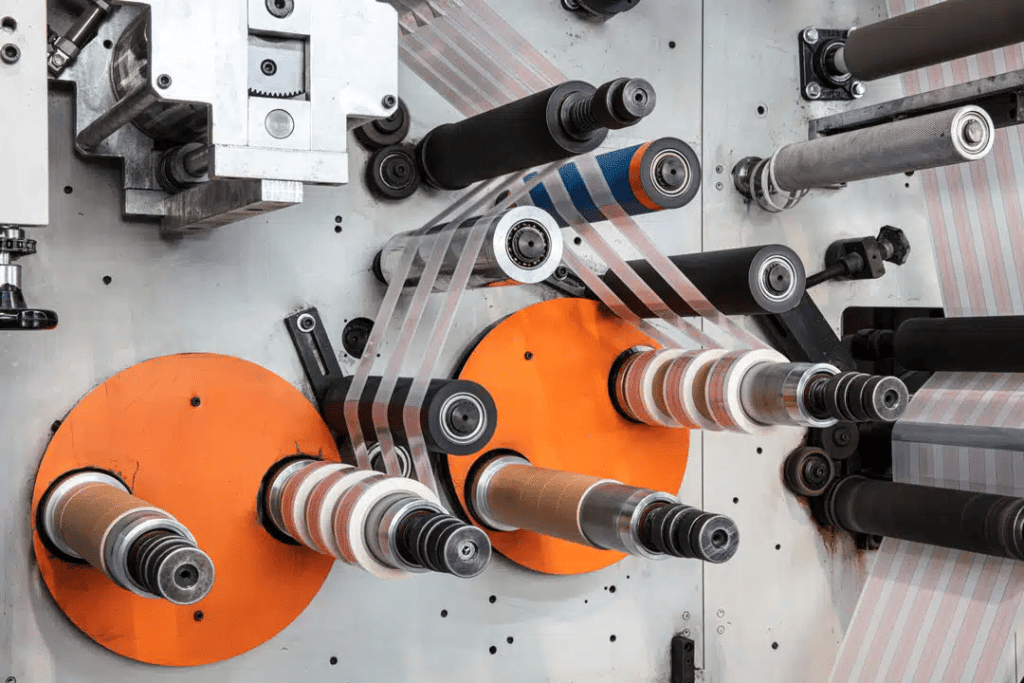

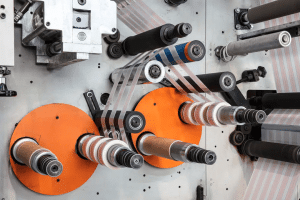

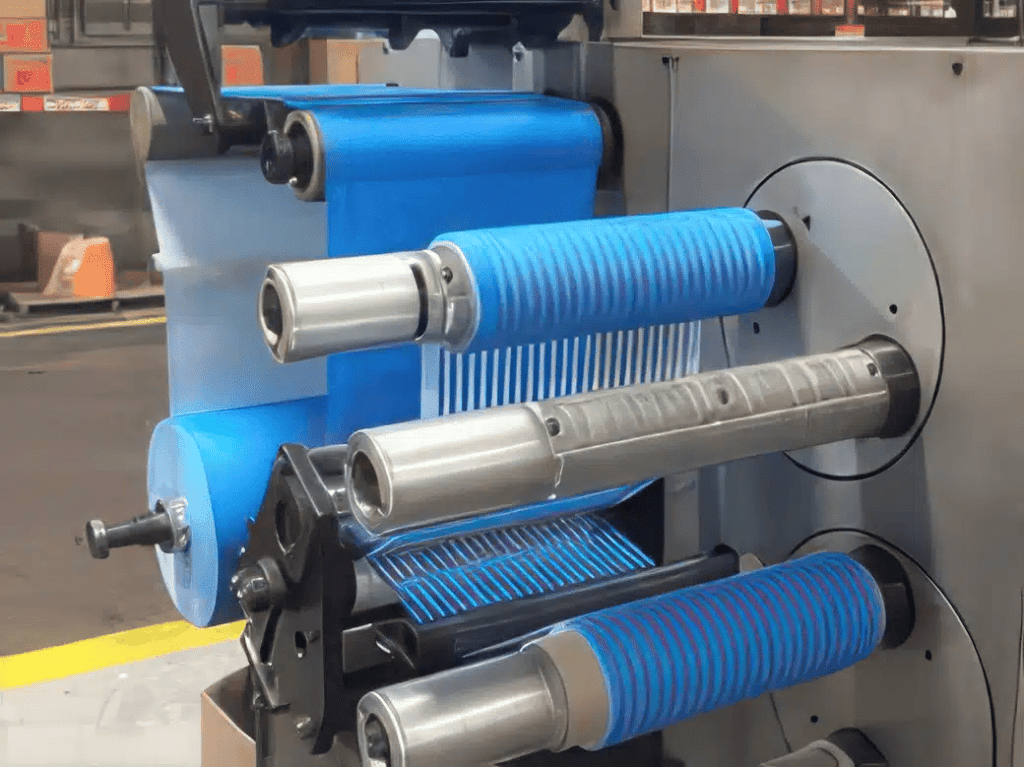

At its core, precision slitting is the process of unwinding a large master roll, running it through a set of extremely sharp, highly accurate blades, and then rewinding the material onto new cores at your exact specified width. The “precision” part of that term is what separates a world-class manufacturing partner from a simple “job shop.” It’s a game of micrometers, where the quality of the edge, the consistency of the width, and the integrity of the material are all at stake.

This process is the essential gateway to manufacturability. Without it, your material simply won’t fit the machine. If your automated assembly line is designed for a 1.25-inch-wide tape, a 40-inch master roll is useless. Precision slitting is what bridges the gap, ensuring the material is perfectly prepared for lamination, die-cutting, or final assembly.

“Optimizing” Your Material: What Does That Actually Mean?

When we say we “optimize” your material through precision slitting, we are talking about several key performance factors. This process isn’t just subtractive; it’s additive in the value it provides.

- Ensuring Perfect Sizing: This is the most obvious benefit. We convert your bulk material into the exact widths required for your equipment, whether that’s dozens of narrow “pancakes” or just a few smaller rolls.

- Guaranteeing Edge Quality: This is arguably the most critical factor. A poorly slit edge can be fuzzy, frayed, or jagged. This leads to parts failing, automated lines jamming, and adhesives “gumming up” or oozing from the side. A precisely slit edge is clean, sharp, and perfectly uniform, which is essential for performance.

- Maintaining Material Integrity: The slitting process must not damage the material itself. It can’t stretch delicate films, delaminate complex laminates, or compress sensitive foams. The material you get back must be in the same pristine condition as the master roll, just in a more usable format.

- Achieving Unbelievable Accuracy: When an engineer specifies a width, they mean it. Our precision slitting capabilities allow us to hold extremely tight tolerances. This level of accuracy is a requirement for high-tech medical, electronic, and aerospace components.

A Method for Every Material

The most important takeaway for any designer or engineer is that there is no “one-size-fits-all” slitting method. The material dictates the process. A method that works perfectly for a polyester film would destroy a soft, open-cell foam. An expert in precision slitting will first analyze your material, its thickness, its abrasiveness, and whether it has an adhesive, and then select the right tool for the job.

At Pepin Manufacturing, we have a wide array of slitting technologies to handle virtually any flexible material. Here are the most common methods and what they’re used for.

Shear Slitting: The Clean Cut for Films and Foils

Think of shear slitting as a pair of high-tech, self-sharpening scissors. This method uses two rotary knives—a male and a female blade—that overlap slightly. As the material passes between them, it’s cut with a clean, precise shearing action. This method is a fantastic choice for a wide range of materials, including paper, films, foils, and nonwovens, as it produces a very clean, crisp, and burr-free edge.

Razor Slitting: The Go-To for Thin Films

Sometimes, the simplest solution is the best. Razor blade slitting does exactly what it sounds like: it uses simple, ultra-sharp razor blades (either in the air or in a groove) to slice the material as it passes by. This is an extremely fast and cost-effective method. It is ideally suited for thin, non-abrasive materials like polyester, vinyl, and other light-gauge films where a new, sharp edge is needed frequently.

Score Cutting (Crush Cutting): Taming Adhesives and Textiles

Score cutting, or crush cutting, is a workhorse for tougher materials. This method uses a hardened steel knife that presses the material against a very hard, smooth anvil (a hardened steel roller). The blade literally “crushes” or “scores” its way through the material. While it may sound harsh, this method is perfect for pressure-sensitive adhesives (PSAs), laminates, and textiles. The crushing action can help “seal” the edge of an adhesive, which helps control adhesive ooze or bleeding—a major problem in many applications.

Single Knife (Lathe) Slitting: The Precision Workhorse

Also known as baloney slitting or lathe slitting, this method is highly versatile. The master roll is rotated at high speed while a single, very sharp circular blade is “fed” into the roll, cutting its way through to the core. It’s like a lathe for flexible materials. This method is excellent for a huge variety of materials, especially adhesive tapes or materials that are already on a liner. It’s known for its high accuracy and ability to cut materials that might be difficult to manage with other unwind/rewind methods.

The Unseen Challenge of Precision Slitting: Tension Control

What separates true experts from amateurs in precision slitting is not just the blade. It’s the art and science of tension control. As the master roll is unwound, sent through the blades, and rewound onto new cores, the tension on the material must be absolutely perfect.

If the tension is too high, the material can stretch, “neck down” (get narrower), or even tear. If the tension is too low, the rewound rolls will be loose, sloppy, and “telescoped,” making them unusable in an automated machine. Our slitting equipment features advanced, closed-loop tension control systems. This ensures that from the outer diameter of the roll to the very core, the material tension is consistent, and your final rolls are perfectly wound and stable.

The Pepin Manufacturing Difference: Quality You Can Trust

When you’re dealing with advanced materials for medical devices or aerospace components, quality is not optional. As an ISO 13485-certified facility, we apply a medical-grade quality management system to every project we run. This means we have full material traceability, documented processes, and a culture of quality that is built into our precision slitting services. We understand that the slit roll we provide you is a critical component of your final product, and we treat it with that level of respect.

Get Started With Your Precision Slitting Project

Don’t let a master roll be a barrier to your production. Precision slitting is the key that unlocks your material’s potential, optimizing it for performance, efficiency, and quality. From the most delicate medical films to thick industrial foams and aggressive adhesives, the right slitting method ensures your material is ready for the assembly line.

If you’re ready to convert your raw materials into perfectly-sized, production-ready components, our team at Pepin Manufacturing is here to help. Contact us today to discuss your project, your material, and your exact specifications. Let’s make sure your material is optimized for success from the very first cut.