Flat bed die cutting is a precision-driven process that plays an essential role in manufacturing. This versatile method allows for the creation of custom components across numerous industries, making it a top choice for a wide range of applications. Whether it’s gaskets, O-rings, or other intricate parts, flat bed die cutting ensures a combination of accuracy and efficiency. At Pepin Manufacturing, we’ve specialized in delivering die cutting solutions that meet the highest standards, helping businesses create the components they depend on.

What Is Flat Bed Die Cutting?

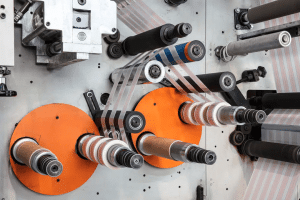

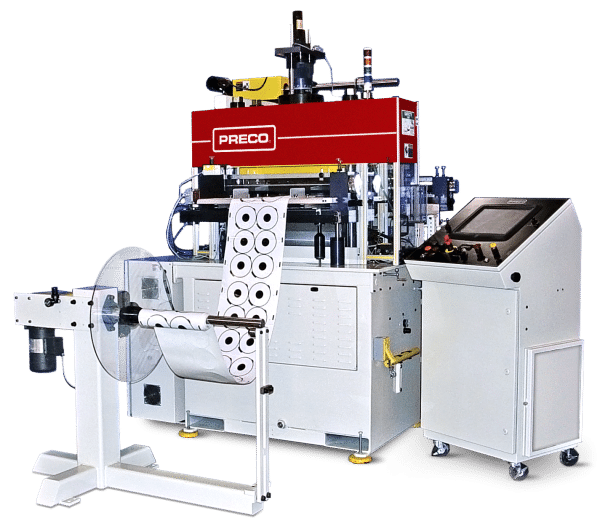

Flat bed die cutting is a manufacturing method that uses a flat steel die and a press to cut or shape materials. This process applies consistent pressure to achieve precise designs, even for intricate or small components. Unlike rotary die cutting, which employs a cylindrical roller, flat bed die cutting is particularly suited for thicker materials or smaller production volumes.

One of this method’s standout features is its versatility. It works with a variety of materials, including foam, rubber, plastics, adhesive-backed materials, and laminates. Flat bed die cutting’s ability to handle diverse materials and designs makes it a popular choice across industries like automotive, healthcare, and electronics.

Applications of Flat Bed Die Cutting

Flat bed die cutting is renowned for its capacity to produce custom parts with a high degree of accuracy. Below, we examine some of the most common applications for this versatile process.

Gaskets

Gaskets are critical components in sealing and preventing leaks in mechanical and industrial systems. Precision is a must in gasket manufacturing to guarantee a reliable fit and performance, especially in demanding environments. Flat bed die cutting offers the precision needed to create intricate gasket designs, ensuring they meet exact specifications. Materials like rubber, foam, and silicone are commonly used, making it possible to produce durable seals for automotive engines, industrial machines, and even medical devices.

O-Rings

O-rings are essential for sealing in countless applications, including fluid systems and machinery. These circular components need to maintain consistent dimensions, as even small variations can lead to performance issues. Flat bed die cutting is an ideal solution for producing O-rings to precise specifications. It handles materials like rubber and elastomers with ease, ensuring consistently high-quality results across production runs.

Adhesive Components

Many industries rely on adhesive-backed components for a variety of applications, such as mounting foam pads, sealing strips, or insulation materials. Thanks to its ability to work with laminated and adhesive-backed materials, flat bed die cutting is perfectly suited for this task. It creates clean, accurate cuts to deliver components that perform as intended in electronics, consumer goods, and healthcare products.

Electrical Insulators

Electrical insulators are vital for system safety and efficiency, tasked with controlling the flow of electricity and preventing shorts or failures. Flat bed die cutting excels in crafting insulators from materials like rubber, plastic films, and specialized composites. Its precision allows for complex designs that fit seamlessly into circuit boards, motors, and other electrical systems.

Medical Components

The medical field demands adherence to stringent hygiene and precision standards, making flat bed die cutting a trusted choice in healthcare manufacturing. It’s often used to create items like wound dressings, surgical tapes, and medical-grade adhesive pads. The flexibility and accuracy of this process ensure components that meet the unique requirements of medical applications.

Benefits of Flat Bed Die Cutting

Flat bed die cutting offers unique advantages, making it one of the most reliable methods for producing custom components. Below are some key benefits that highlight its value:

High Precision

Accuracy is one of the biggest strengths of flat bed die cutting. Detailed designs are achievable with minimal variability, which is crucial for industries such as aerospace, healthcare, and automotive, where tolerances are tight.

Material Versatility

Few manufacturing methods can match the range of materials that flat bed die cutting can handle. Whether it’s thin adhesive-backed films or thick rubber sheets, this process accommodates a vast array of material types and thicknesses.

Cost Efficiency for Smaller Runs

For projects involving short production runs or prototypes, flat bed die cutting proves to be highly cost-effective. Unlike rotary die cutting, which often necessitates large-scale production to be economical, flat bed methods excel at smaller, tailored projects.

Customization

Flat bed die cutting offers nearly limitless possibilities for customization. From irregularly shaped gaskets to uniquely designed adhesive-backed products, the process provides the versatility to meet exact project requirements.

Reduced Material Waste

Efficient material usage is another hallmark of flat bed die cutting. The accuracy it offers minimizes waste, which not only reduces costs but also supports sustainability goals.

Quick Setup and Production

The straightforward nature of flat bed die cutting allows for faster setup times, leading to quicker turnaround for production runs. This can be a critical factor when deadlines are tight or immediate delivery is required.

Industries Utilizing Flat Bed Die Cutting

The adaptability and precision offered by flat bed die cutting services attract industries that depend on high-quality, custom components. These include:

- Automotive: Common components include gaskets, seals, and insulation, all integral to vehicle durability and performance.

- Healthcare: Products such as wound care dressings, surgical tapes, and disposable medical items are manufactured with exacting standards.

- Electronics: Flat bed die cutting is widely used to produce insulating materials, EMI/RFI shielding, and precision adhesive components.

- Industrial Manufacturing: Applications range from spacers and foam inserts to custom seals for heavy-duty equipment.

- Aerospace: Given the unique challenges of aerospace components, flat bed die cutting ensures the creation of detailed, lightweight parts that perform under pressure.

Explore Flat Bed Die Cutting Services Today

Flat bed die cutting has become a trusted manufacturing process for creating precise, high-quality components. Its ability to handle a variety of materials and meet exacting standards makes it indispensable in industries such as automotive, healthcare, and electronics. Whether you need gaskets, O-rings, or adhesive-backed parts, this process ensures a perfect balance of accuracy and reliability.

At Pepin Manufacturing, we’re proud to bring expertise and innovation to every flat bed die cutting project. With a commitment to quality and customer satisfaction, we’re here to help you tackle your most challenging production needs. If you’re ready to elevate your manufacturing process with precision die cutting, get in touch with us today online or by calling 800-291-6506.