Urethane Film Slitting Services

Precision Slitting for Urethane and Flexible Film Materials

Request A Quote

Home » Contract Converting » Urethane Film Slitting Services

Urethane film plays a vital role in many medical, industrial, and consumer applications, which means its conversion requires precision, consistency, and dependable handling. Pepin Manufacturing, Inc., located in Lake City, MN, provides urethane film slitting services designed to prepare flexible materials for a wide range of downstream processes.

From narrow-width rolls to controlled tension slitting, the team at Pepin Manufacturing works to deliver slit film that supports production efficiency and material performance. With decades of experience and a steady commitment to quality, the company serves as a trusted partner for businesses that rely on accurately prepared film materials.

A Minnesota Manufacturer With Decades of Expertise

Since its founding in 1993, Pepin Manufacturing, Inc. has operated as a family-owned, U.S.-based contract manufacturer serving medical, industrial, aerospace, consumer, and retail markets. The company’s Lake City facility, located at 1875 Highway 61 South, houses a wide range of converting equipment and supports projects that range from mid-size orders to full-scale production.

As an ISO-13485 certified manufacturer, Pepin Manufacturing maintains established quality processes, documentation systems, and traceability measures that benefit customers who work with regulated products or sensitive materials. Over time, the company has built long-standing relationships with partners who depend on consistency, communication, and manufacturing reliability.

What Urethane Film Slitting Involves

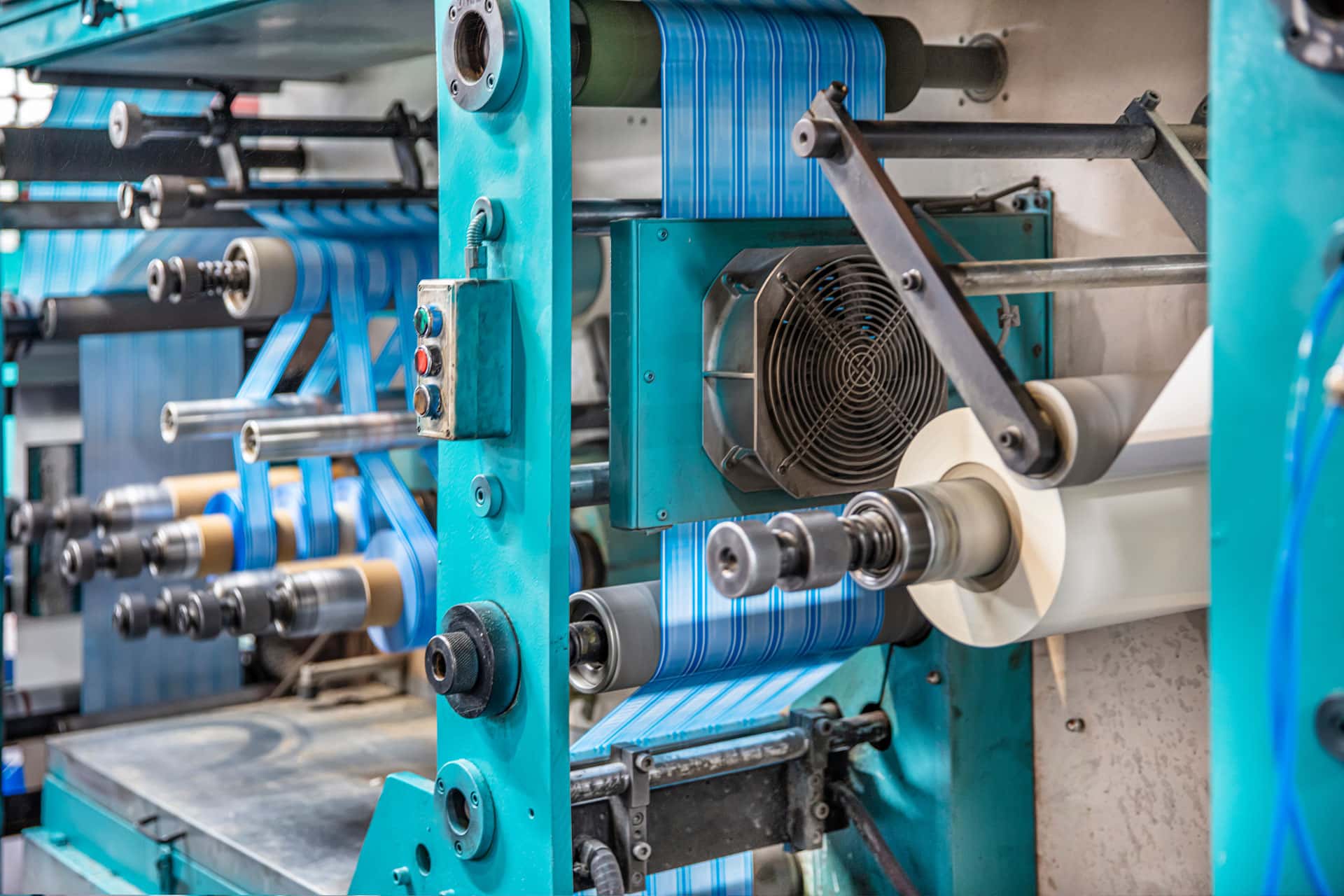

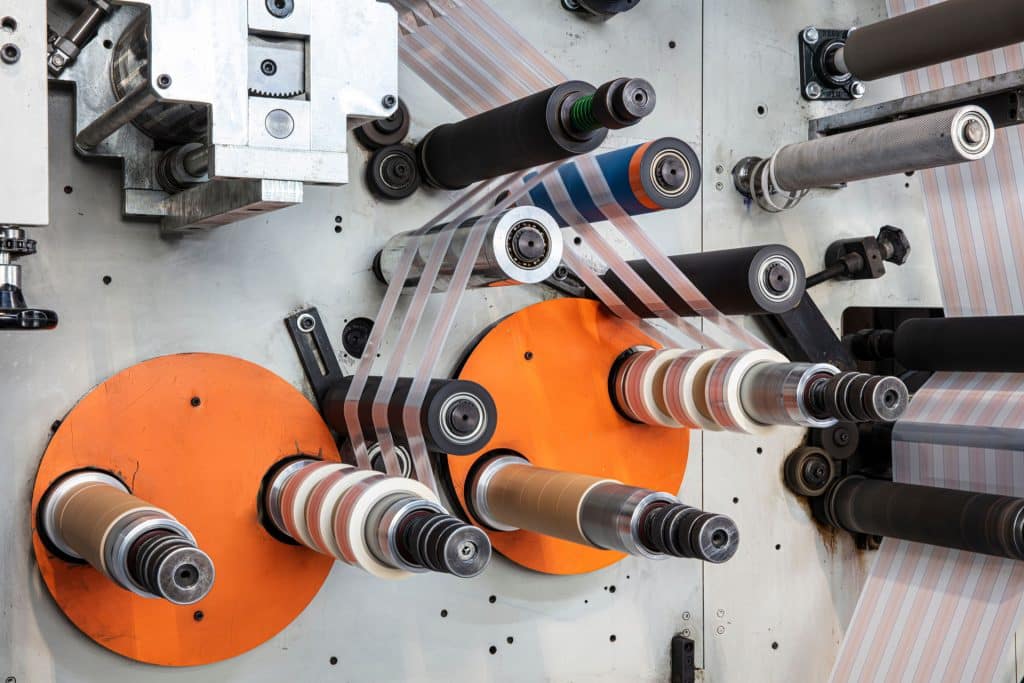

Film slitting is the process of converting wide rolls of material into narrower, precisely cut rolls suited for specific applications or downstream processing requirements. When that material is urethane film, the slitting process demands careful control over tension, edge quality, and substrate integrity. Pepin Manufacturing uses precision slitting equipment capable of producing clean, consistent edges across a variety of flexible materials, including urethane, medical films, laminates, nonwovens, tapes, and similar substrates. Careful attention is given to width tolerances, slitting method selection, and roll-to-roll handling to ensure that the film remains suitable for its next stage of manufacturing.

For customers who plan to die-cut, laminate, package, or assemble final components, the accuracy of slit rolls can influence material usage, machine compatibility, and overall production flow. By preparing urethane film with consistent widths and clean edges, the slitting process helps streamline later fabrication steps and supports efficient inventory management.

How Pepin Manufacturing Slits Urethane Film

Every slitting project begins with a review of the material, its properties, and the application it will support. Pepin Manufacturing works with clients to identify the ideal roll width, core size, outer diameter, and slitting method for their substrate. Razor, score, or shear slitting may be recommended depending on the film’s thickness, finish, and mechanical characteristics. Once specifications are determined, the Lake City team prepares the equipment, establishes tension settings, and begins carefully monitored production.

Throughout the process, quality control plays a central role. Each roll is checked for width accuracy, surface quality, and uniformity. The company’s ISO-13485 certified quality management program reinforces consistent inspection practices and helps ensure proper documentation and traceability for industries that require structured oversight.

When needed, urethane film slitting can be combined with additional converting services in the same facility. Pepin Manufacturing offers die-cutting, laminating, printing, hydrogel processing, contract packaging, and light assembly. By keeping multiple steps under one roof, customers can reduce transportation between vendors and maintain a smoother production schedule.

Industries and Applications That Use Slit Urethane Film

Urethane film is valued for its flexibility, clarity, breathability, and durability. These qualities make it useful in medical device components, wound-care materials, diagnostic products, wearables, and various sensor technologies. Many of these applications rely on consistent film preparation because downstream manufacturing often involves delicate adhesives, advanced coatings, or precision die-cutting systems.

Industrial applications also benefit from slit urethane film, including insulation layers, surface protection films, gasketing substrates, and adhesive tape components. The material’s strength and versatility make it suitable for demanding environments and specialized assemblies. Consumer and cosmetic brands may use slit films for packaging layers, personal-care products, liners, and peel-and-stick components. In each case, cleanly slit film helps maintain an attractive appearance and predictable performance throughout additional converting steps.

Why Companies Choose Pepin Manufacturing

Pepin Manufacturing brings more than three decades of experience to every converting project. Its team has worked with a broad range of materials and understands how different substrates behave during slitting, laminating, or die-cutting processes. The company’s domestic production environment in Lake City provides consistent communication, shorter logistical timelines, and U.S.-based quality standards. Its ISO-13485 certification further supports customers who require documented processes and dependable oversight.

The ability to integrate slitting with additional converting and packaging services allows Pepin Manufacturing to support customers through multiple stages of production. Whether preparing urethane film for specialized medical applications or for industrial product assembly, the company focuses on accuracy, responsiveness, and the needs of each client.

Start Your Urethane Film Slitting Project

Businesses seeking urethane film slitting services in Lake City, MN, can contact Pepin Manufacturing to discuss material requirements, roll specifications, and production needs. The team is available to answer questions, review project details, and prepare a customized quote. Contact Pepin Manufacturing or visit the facility to begin planning your next project.