Film Slitting Services

Contract Converting Support Rooted in Precision and Experience

Request A Quote

Home » Contract Converting » Film Slitting Services

Pepin Manufacturing, Inc. provides film slitting services in Lake City, MN, for companies seeking dependable converting support with detailed attention to material handling and accuracy. As a long-standing manufacturer operating from an ISO 13485–certified facility, the team works with a wide range of flexible materials and substrates for medical, industrial, cosmetic, and consumer applications.

Located at 1875 Highway 61 South, Pepin Manufacturing has spent decades refining converting solutions that help customers move materials smoothly from wide-format stock to finished roll configurations suitable for downstream use. Every project is approached with a focus on consistency, traceability, and professional handling of delicate or specialty films.

Understanding Film Slitting and Its Role in Manufacturing

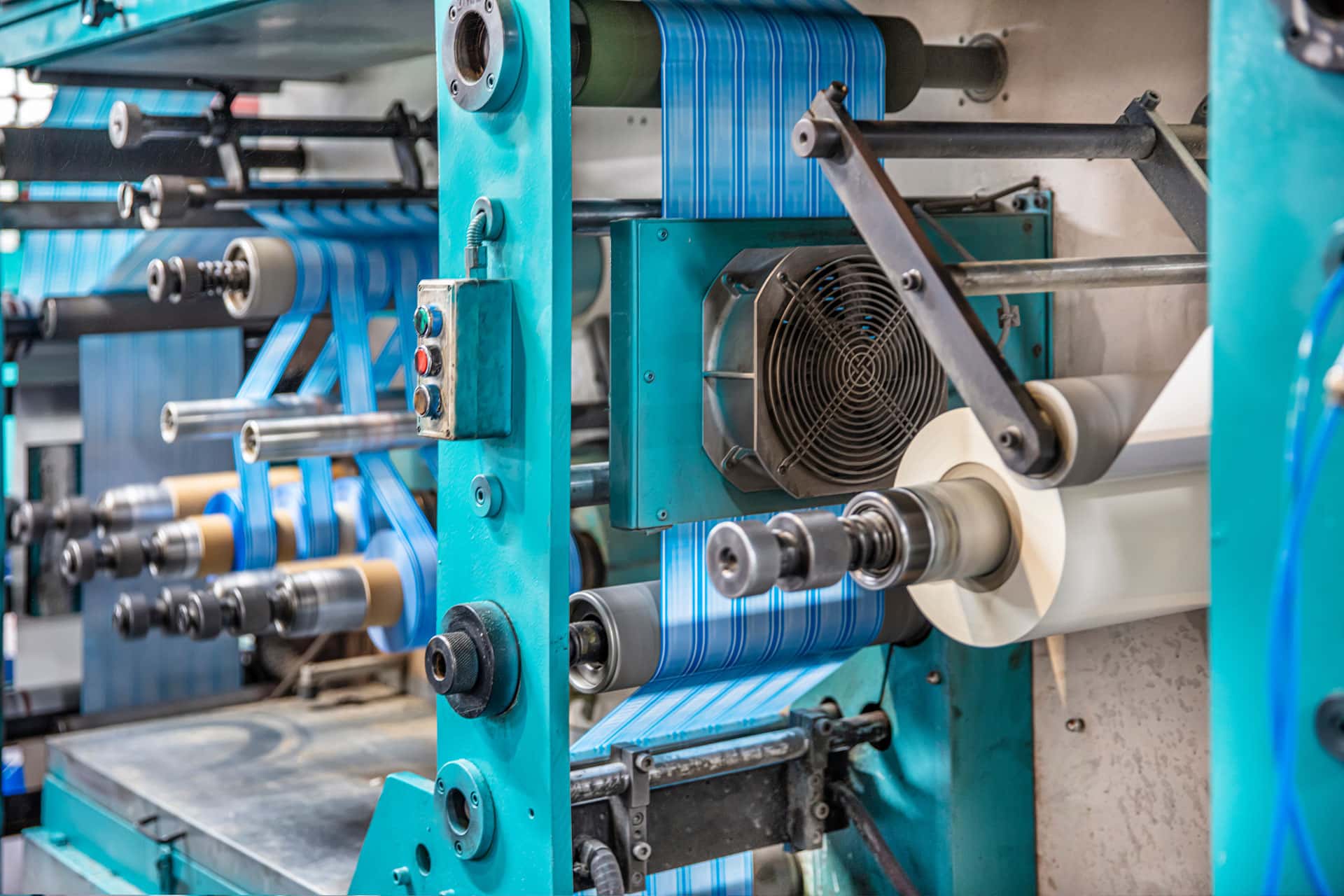

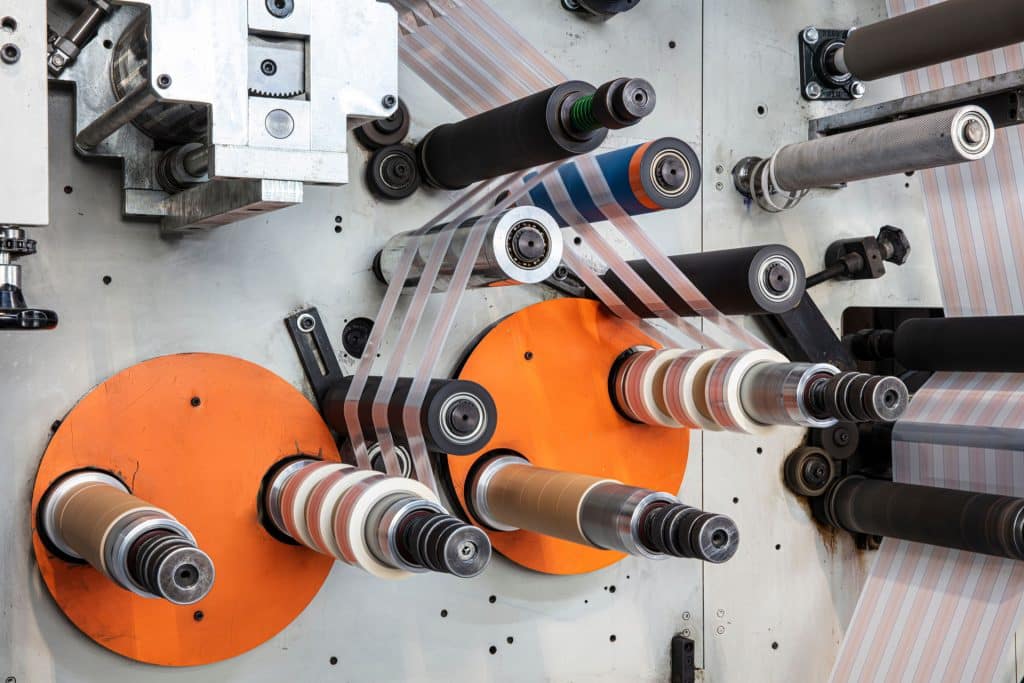

Film slitting is the process of cutting large master rolls of film or similar materials into narrower, application-ready rolls. This step supports many stages of production, from adhesive coating to die cutting to packaging. In many industries, film slitting must accommodate sensitive substrates, specific roll widths, or tight tolerances. Materials such as pressure-sensitive adhesives, multilayer structures, release liners, or barrier films often require careful tension control and cutting methods.

Film slitting also helps manufacturers streamline inventory, reduce waste, and prepare materials for efficient machine loading. By converting wide rolls into precise widths, companies can better align their materials with equipment specifications, assembly requirements, or product designs.

Film Slitting Capabilities at Pepin Manufacturing

Pepin Manufacturing offers several slitting approaches designed to accommodate different material types and performance needs. Razor slitting, shear cutting, and score slitting are used depending on the characteristics of the film and the desired edge quality. Each method is selected with the goal of delivering consistent cuts while maintaining material integrity. The team also works with various roll cores, including 1-inch, 3-inch, and 6-inch options, enabling compatibility with a wide range of equipment setups.

Materials commonly processed include adhesive films, nonwovens, foams, hydrogel sheets, release liners, laminates, and industrial or medical-grade films. The environment in Lake City supports these operations with controlled processes and documented workflows that align with the expectations of medical device manufacturers, industrial producers, and consumer goods companies.

Because film properties vary significantly among applications, Pepin Manufacturing evaluates each material to determine the right combination of tension, speed, blade style, and handling method. This makes it possible to produce rolls suitable for die cutting, laminating, packaging, assembly, or other production steps.

A Facility Prepared for Diverse Project Needs

Pepin Manufacturing’s Lake City location houses converting equipment, quality systems, and production teams that support projects of many sizes. As a family-owned company established in 1993, PMI has integrated additional capabilities alongside slitting, including laminating, printing, packaging, and die cutting. This environment allows customers to pursue single-service slitting projects or multi-step converting sequences under one roof.

The plant’s ISO 13485 certification supports traceability and documentation for customers who require structured processes. Materials intended for medical or diagnostic use benefit from these controlled workflows, and industrial clients gain access to consistent procedures and established inspection practices. With the company’s additional facility in Wabasha, MN, supporting broader production output, customers can coordinate projects that range from quantities to regular production runs.

Industries Supported Through Film Slitting

Film slitting services in Lake City support multiple market segments with unique material demands. In the medical and healthcare industries, slitting helps prepare materials for wound care components, diagnostic strips, adhesive patches, wearable device materials, and packaging layers. These products often require sensitive handling or specialty substrates, and the slitting process plays a foundational role in preparing materials for further conversion.

Industrial and electronics applications rely on slit films for insulation layers, protective barriers, laminated structures, bonding tapes, or components used inside assemblies. Film slitting also supports cosmetic and consumer goods producers that work with hydrogel sheets, liners, pressure-sensitive patches, and thin films used in retail packaging or personal-care items. By offering material-specific slitting options, Pepin Manufacturing helps companies prepare consistent roll stock suited to their equipment and production strategy.

Why Companies Work With Pepin Manufacturing

Customers seeking film slitting services often look for a partner with experience, flexibility, and a manufacturing setting that emphasizes quality. Pepin Manufacturing offers all three. The company’s long history in contract converting provides teams with a detailed understanding of material behavior and the handling requirements of various substrates. Its vertically integrated structure allows customers to engage in slitting alone or combine slitting with other converting operations. The Lake City facility provides a central location for communication, coordination, and ongoing project development.

Partner With Pepin Manufacturing for Trusted Film Slitting Services

Organizations looking for dependable film slitting services in Lake City, MN, can connect with Pepin Manufacturing to explore material options, discuss roll specifications, or begin planning a converting project. The team offers guidance based on material type, desired widths, and downstream production requirements. To start a conversation about your project, contact Pepin Manufacturing today and learn how their slitting capabilities can support your operational goals.