In modern manufacturing—especially in sectors such as medical, industrial, and electronics—materials are becoming more advanced, more sensitive, and more performance-critical. As a result, converting partners play an increasingly important role in ensuring that materials arrive downstream in the exact condition required for seamless processing. Among these converting services, precision film slitting stands out as one of the most important steps in maintaining material integrity, reducing production waste, and ensuring components perform as intended in their final application.

Manufacturers that depend on films, foils, adhesives, and laminated structures know that even the smallest variation in slit width or edge quality can disrupt automated assembly lines, create fit-and-function issues, or generate costly scrap. Partnering with a slitting provider equipped with advanced equipment and deep technical expertise can be the key to maintaining consistency, improving yield, and avoiding production delays. Pepin Manufacturing has built its reputation on delivering this level of precision and reliability, helping clients across industries streamline operations and improve product outcomes.

What Film Slitting Is—and Why It Matters in Modern Manufacturing

At its core, film slitting is the process of converting large master rolls of material into narrower, application-specific widths. While the process may appear simple, precision slitting is a technical discipline requiring expertise in material behavior, equipment configuration, tension control, and quality assurance.

During slitting, a roll is unwound, passed through a series of precision blades or rotary knives, and rewound into smaller rolls. When done correctly, this produces clean, uniform edges and exact widths that integrate seamlessly into downstream processes such as laminating, coating, printing, die cutting, or automated assembly.

However, when slitting is inconsistent, it can introduce challenges such as:

- Misaligned edges that affect automated feeding

- Uneven winding that leads to telescoping or blocking

- Particulate generation or edge damage that interferes with end-use performance

- Variable widths that create yield loss or equipment jams

This is why choosing a high-accuracy slitting partner is critical for manufacturers that rely on precision performance.

The Importance of Tight Tolerances and Superior Edge Quality

In industries where every detail matters, the precision of a slit roll becomes directly tied to product quality. Engineers and procurement teams often focus heavily on the materials themselves—film thickness, adhesive chemistry, carrier type, barrier properties—but the quality of the slit edges is just as important.

In medical applications, for example, edge quality can influence how materials laminate, bond, or seal. Rough or inconsistent edges may lead to particulate contamination, wrinkling, or sealing failures inside a device. In industrial or electronics manufacturing, a slitting error can become a bottleneck, causing misfeeds or forcing operators to slow down automated processes to compensate for width variability. High-quality edge control ensures that the material behaves predictably during further converting or assembly.

Precision slitting is also critical when working with sensitive materials that stretch, curl, or distort under tension. The ability to maintain stable, repeatable slitting under the right tension profile helps protect these materials from defects that may not appear until the product reaches the end user.

All these factors demonstrate why manufacturers rely on partners like Pepin Manufacturing; not simply for slitting capability, but for the consistency that ensures predictable performance.

Materials Pepin Manufacturing Can Slit

Pepin’s slitting expertise extends across a broad range of flexible materials commonly used in regulated and high-performance industries. Materials include, but are not limited to:

- Polymer films

- Medical and industrial foils

- Pressure-sensitive adhesives

- Multi-layer laminates

- Specialty coated materials

- Release liners

- Flexible substrates used in electronics, sensors, and diagnostics

Each material type presents unique challenges—from stretch characteristics, to adhesive ooze, to static buildup, to surface-sensitive coatings. Pepin’s combination of advanced machinery and experienced operators ensures that each material is managed according to its specific behavior to protect quality throughout the entire slitting process.

Why an Experienced Slitting Partner Matters

Many manufacturers underestimate how much the quality of slit rolls affects production efficiency. Working with an experienced slitting service provider like Pepin Manufacturing offers several advantages:

1. Consistency Across Every Roll

Consistency may be the most important attribute in slitting. Manufacturers depend on rolls that load easily, run smoothly, and perform predictably in every batch. Pepin’s internal quality controls, standardized processes, and advanced equipment help ensure that every roll meets the same performance expectations.

2. Scalability for Growth and Changing Needs

Production needs change over time as new product variations are introduced, volumes shift, or materials evolve. Pepin’s capacity and operational flexibility allow manufacturers to scale their slitting requirements without worrying about delays, variability, or supply chain bottlenecks.

3. ISO-Certified Quality Systems

Pepin Manufacturing operates under documented and audited quality systems that support regulatory and industry compliance. This provides assurance that every roll has been produced following defined procedures, monitored controls, and traceable documentation.

4. Reduction of Scrap, Rework, and Line Downtime

Poorly slit material often results in significant hidden costs: wasted product, halted lines, operator intervention, and equipment resets. By delivering accurate, stable slit rolls, Pepin helps manufacturers reduce these inefficiencies and maintain continuous production flow.

5. Technical Expertise for Complex Requirements

Some materials simply cannot be slit effectively without specialized knowledge. Whether it’s managing tension for ultra-thin films or ensuring clean edges on adhesive-backed structures, Pepin’s operators and engineers understand how to configure equipment to achieve precise results.

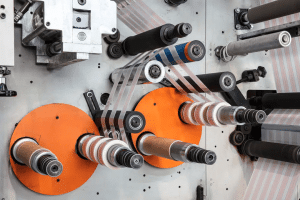

Pepin Manufacturing’s Advanced Equipment and Custom Capabilities

What sets Pepin apart is the combination of seasoned expertise and investments in advanced slitting technology. Pepin’s equipment line-up includes precision rewind slitters, narrow-web slitters, and custom-configured machinery designed to handle unique materials or complex structures. This allows Pepin to support a wide range of roll widths, material types, and performance requirements.

Pepin can also collaborate closely with clients to tailor the slitting process to their application needs—whether that includes tension adjustments, specific roll OD targets, adhesive-sensitive handling, or specialized packaging requirements. This collaborative approach ensures that the finished rolls integrate seamlessly into the client’s manufacturing flow.

Real-World Example: Improving Yield for a High-Volume Manufacturer

A recent client in the industrial materials sector was experiencing significant scrap due to inconsistent edge quality and width variation from another supplier. Their automated line frequently jammed, forcing operators to slow the line speed or manually trim edges before feeding the material.

After transitioning their slitting operations to Pepin Manufacturing, the client saw immediate improvements. The rolls loaded cleanly, widths remained stable from start to finish, and the consistent winding eliminated the telescoping that previously caused breakdowns. As a result, their scrap rate dropped substantially and overall productivity increased, unlocking both cost savings and improved machine uptime.

Partner With Pepin Manufacturing for Precision Slitting Success

Precision slitting is more than a converting service; it’s a foundational step that can impact every stage of your manufacturing process. When materials enter your facility properly slit, wound, and prepared, the entire production line benefits from increased efficiency, reduced waste, and improved performance.

Pepin Manufacturing brings decades of slitting expertise, industry-trusted quality systems, and a commitment to supporting the unique needs of every client. Whether you work with films, adhesives, foils, or multi-layer laminates, Pepin has the capability and experience to deliver consistent, high-quality results.

To learn more about how Pepin’s slitting services can support your production goals, contact our team today.