For project managers, engineers, and designers, the challenge is often twofold: you need to scale production to high volumes, but you cannot sacrifice precision in the process. A single, inconsistent part in a medical device or an aerospace component can lead to catastrophic failures. This is where the power of precision rotary die cutting becomes clear. This advanced manufacturing process is the key to achieving identical, high-quality components, whether you’re producing thousands of units or millions.

Explore how precision rotary die cutting works, why it is the superior choice for high-volume projects, and how it maintains exacting standards of consistency every step of the way. Understanding this process is the first step to optimizing your production, reducing waste, and ensuring your final product performs flawlessly every time.

What Exactly Is Precision Rotary Die Cutting?

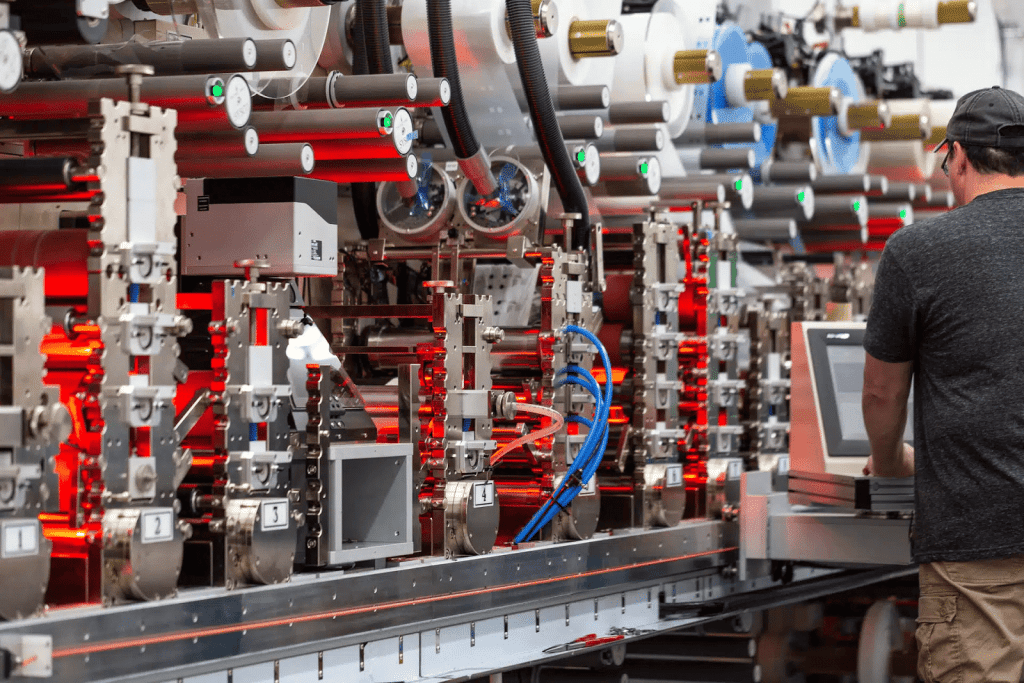

At its core, precision rotary die cutting is a fabrication process that uses a custom-engineered cylindrical die to cut or shape flexible materials. Think of it as a highly advanced, industrial-strength cookie cutter that operates at incredible speeds. The material, often a web of tape, foam, or film, is fed continuously through a press. As it passes under the rotating die, the desired shape is cut with extreme accuracy. This continuous, high-speed motion is what fundamentally separates it from other methods, like flatbed die cutting, making it the ideal solution for high-volume production runs.

The Mechanics: How Speed and Consistency Work Together

You might think that high speed would compromise precision. With rotary die cutting, the opposite is true. The process is designed for speed. The custom-engineered rotary die is a solid, single piece of tooling. As it rotates at a consistent speed, it makes the exact same cut, in the exact same place, on every single rotation.

This mechanical repetition is the engine of consistency. There is no variance from one cut to the next. Unlike manual or slower processes that can introduce human error or machine drift, the rotary press is set for a specific tolerance and material. It then executes that command thousands of times per hour, delivering a level of repeatability that is simply unattainable with other methods.

Why Is “Good Enough” Never Good Enough?

In the industries we serve, there is no such thing as “almost right.”

- In the medical field, a diagnostic device or wound care product must be perfect. An inconsistent cut could compromise a sterile seal or the effectiveness of a component.

- In aerospace and defense, components must withstand extreme conditions. A gasket or insulation part that is even a fraction of a millimeter off spec could fail under pressure.

- In industrial applications, seals and gaskets prevent leaks and damp vibration. Consistency is directly linked to reliability and safety.

Precision rotary die cutting addresses this need by producing parts that are not just similar, but truly identical. This eliminates the guesswork and risk from your supply chain.

Achieving Tight Tolerances at Scale

The term “tight tolerances” is often used, but what does it mean for your project? At Pepin Manufacturing, our state-of-the-art equipment allows us to maintain tolerances “often within thousandths of an inch.” This is a level of precision that is critical for complex geometries and detailed cut patterns. When your design requires a part to fit perfectly within an assembly or to align with other components, this tolerance is non-negotiable. Rotary die cutting is the only process that can reliably deliver this precision across a full-scale mass manufacturing run.

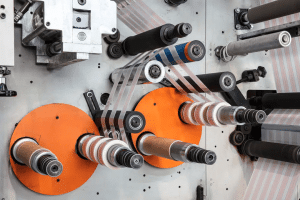

Material Versatility: Consistency Across Substrates

Consistency isn’t just about the shape; it’s also about how the material itself is handled. Different materials behave in different ways. Adhesives can gum up tooling, thin films can stretch, and foams can tear. Part of the expertise in rotary die cutting lies in managing these variabilities.

Our team has decades of experience converting a wide range of flexible materials, including:

- Medical-grade adhesives

- Pressure-sensitive tapes

- Foams and nonwovens

- Thin films and foils

- Hydrogels and hydrocolloids

- Specialty laminates

We engineer the process around the material. This ensures that whether we are cutting a delicate nonwoven fabric or a robust industrial tape, the final part is clean, uniform, and free of defects.

Advanced Techniques for Complex Applications

Modern products are rarely simple. They often involve multiple layers, complex adhesives, or unique shapes. This is where advanced rotary die cutting techniques shine, delivering consistency in even the most complex designs.

Kiss Cutting

This is a perfect example of precision. Kiss cutting involves cutting through the top layer of a material (like an adhesive part) while leaving the liner or backing paper completely intact. This requires incredibly precise depth control, measured in microns. For any peel-and-apply product, consistent kiss cutting is essential for functionality.

Multi-Layer Laminations

Many products require bonding multiple layers of different materials before cutting. Our rotary die cutting capabilities allow us to do this in one continuous process. We can laminate several layers and then die-cut the final component, ensuring perfect alignment between all layers. This streamlines manufacturing and ensures the complex part is produced consistently every time.

Island Placement

For more advanced applications, we can perform island placement. This process involves accurately placing a smaller, die-cut “island” of material onto a larger web of material, all in line. This is vital for creating complex electrodes, diagnostic strips, or multi-part components.

Quality You Can Measure: The ISO 13485 Standard

At Pepin Manufacturing, our commitment to consistency is backed by our ISO 13485 certification. This is a rigorous quality management standard specifically for medical devices. While it’s a requirement for our medical clients, we apply this same level of quality control to all our projects.

This certification means we have full traceability for all raw materials. It means every step of the manufacturing process is documented, validated, and repeatable. For you, our customer, it provides peace of mind. It’s an independent verification that our processes for rotary die cutting are built on a foundation of quality and consistency.

How Consistency Impacts Your Bottom Line

Ultimately, consistent manufacturing has a direct, positive impact on your project’s success and your budget.

- Reduced Material Waste: Precision rotary die cutting is designed to minimize scrap. By optimizing material usage and nesting parts efficiently, we improve yield and reduce your material costs.

- Improved Cost Efficiency: High-speed production means less machine time per part. This efficiency translates directly into a more competitive unit price, especially at high volumes.

- Faster Time to Market: By streamlining production and ensuring part quality from the start, we eliminate delays caused by rework or quality control failures. Your assembly line gets the parts it needs, when it needs them, allowing you to get your product to market faster.

Partner With Pepin Manufacturing for Your Precision Rotary Die Cutting Needs

High-volume consistency is not a mystery—it’s the result of a precise, well-managed, and advanced manufacturing process. Precision rotary die cutting is the engine that drives that consistency. It allows you to scale your project from prototype to mass production without ever sacrificing the quality or tolerances your design demands.

If you are ready to bring a new level of consistency and quality to your next project, our team at Pepin Manufacturing is here to help. Contact us today to discuss your application, request a quote, or schedule a consultation with our engineering team. Let’s build something great together.